New materials and designs transferred to practice

The development of innovative materials, such as textile-reinforced concrete or ultra-high performance concrete, makes it possible to build slender structures while responding to the requirements of modern architecture that involve larger spans and thin structural components. This article outlines the particular characteristics of these two materials and presents some project examples.

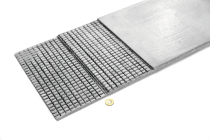

The use of non-corroding technical textiles, such as alkali-resistant (AR) glass or carbon, enables a significant reduction in the concrete covers required in reinforced concrete construction in order to ensure durability, which results in extremely slender precast components. The textile materials are mesh reinforcements with grid sizes between 5 and 45 mm. These fine meshes require the use of a so-called fine-grained concrete, which is characterized by maximum aggregate diameters between 0.6 and 8 mm. In addition, this filigree particle structure can be combined with special curing methods to achieve state-of-the-art architectural concrete surfaces, which makes textile-reinforced concrete the perfect choice for facades.

For example, the 10,000 m² facade of the Leiden Community College (Fig. 1) was clad in 30 mm thick, ventilated textile-reinforced concrete panels measuring 642 by 1,780 mm. Due to the building height of about 50 m and its location close to the coast, the structure was to be designed to resist very high wind loads of up to 3.0 kN/m², which resulted in demanding reinforcement specifications. A carbon reinforcement was applied that can resist a characteristic tensile stress of approx. 1,800 N/mm² in the structural component [1].

Textile-reinforced concrete is used not only for ventilated facade systems but also in sandwich construction, where concrete covers from as low as 15 mm are possible. These minimized load-bearing layers respond to the growing demand for thermal insulation, which can be installed in greater thicknesses whilst retaining the same thickness of the overall structure [2].

Moreover, textile-reinforced concrete is also suitable for bridge construction. In 2010, a pedestrian bridge was completed in the German town of Albstadt-Lautlingen that includes an extremely slender superstructure consisting of textile-reinforced concrete (Fig. 2). The bridge structure has a length of about 100 m and consists of six precast components in lengths of up to 17.20 m. It is characterized by a slenderness (height to length) ratio of only 1:35 [3], [4].

Ultra-high performance concrete

Ultra-high performance concrete (UHPC) is a concrete with a particularly dense structure whose strength results from its high packing density, high binder ratio and added steel fibers. Depending on the mix composition and production process, compressive strengths clearly in excess of 150 N/mm² can be achieved without heat curing.

In compression, UHPC shows an almost linear-elastic deformation behavior until failure, and has a significantly greater modulus of elasticity compared to normal concrete (between 50,000 and 55,000 N/mm²). Its increased strength and linear-elastic behavior ensure that a very high amount of energy is stored and that the UHPC shows sudden failure once the ultimate tensile or compressive load is exceeded. For this reason, fibers are added to the concrete that ensure a ductile post-failure behavior. Tests carried out at the Institute of Concrete Structures at RWTH Aachen showed that this behavior is achieved with fiber contents as low as 0.9 percent by volume.

Some projects have already been completed with his material, including the Gärtnerplatz Bridge in Kassel or Sherbrooke Bridge in Canada.

REFERENCES . LITERATUR

[1] Kulas, Christian; Schneider, Maike; Will, Norbert; Grebe, Reiner: „Hinterlüftete Vorhangfassaden aus Textilbeton – Tragverhalten und Ausführung“. Bautechnik 88 (2011), Heft 5, 271-280.

[2] Horstmann, Michael; Hegger, Josef: „Sandwichfassaden aus Textilbeton – experimentelle Untersuchungen“. Bautechnik 88 (2011), Heft 5, 281-291.

[3] Hegger, Josef; Goralski, Claus; Kulas, Christian: „Schlanke Fußgängerbrücke aus Textilbeton – Sechsfeldrige Fußgängerbrücke mit einer Gesamtlänge von 97 m“. Beton- und Stahlbetonbau 106 (2011), Heft 2, 64-71.

[4] Hegger, Josef; Kulas, Christian; Raupach, Michael; Büttner, Till: „Tragverhalten und Dauerhaftigkeit einer schlanken Textilbetonbrücke – Eine 97 m lange Fußgängerbrücke mit einer Bewehrung aus AR-Glasfilamenten“. Beton- und Stahlbetonbau 106 (2011), Heft 2, 72-80.

TEXT: Hegger, Josef; Kulas, Christian; Gallwoszus, Joerg - RWTH Aachen