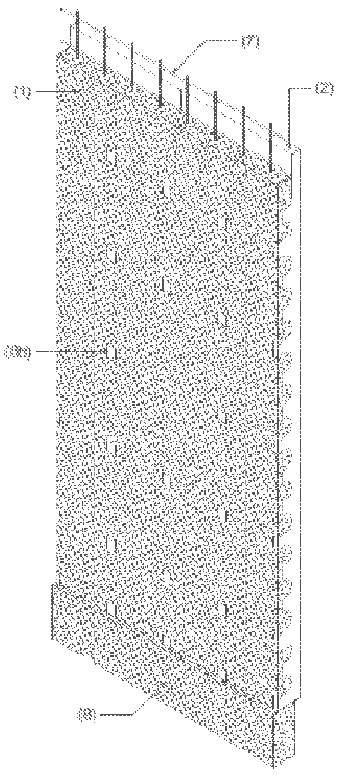

Solid walls with thermal insulation

Time is money. This is especially true for the construction site. Apart from the time it takes to construct the building actually, the time required for the installation of the external wall insulation has to be taken into account, among other things, too. Depending on the dimensions of the building, several days have to be considered for this purpose. However, this is achieved even quicker now by means of the precast technology of F.C. Nüdling. As of now, the concrete specialist located in Fulda (Germany) is offering his tried and tested FCN solid walls completely with thermal insulation. In this way, two work steps can be managed at one go.

An utterly innovative manufacturing and handling system allows lining the FCN solid walls with thermal insulation (EPS) already in the factory using a bonding technique and carrying them to the construction site ready for use. The surface of the insulating material is manufactured by means of precise machine technology, thus providing an accurate and extremely smooth processing surface. This allows treating the walls with the finishing coat of plaster immediately after erection of the same. Special scaffolding is no longer necessary for the application of plaster, just a paint scaffold will do.

The construction of the skeleton combined with thermal protection (Thermo Casing) enables shortening the construction time considerably as the interior work can be done irrespective of the outdoor temperature and weather conditions. The supplier adapts the thicknesses of walls and insulation to the specific project. In this way, waste is avoided and the construction site remains neat and clean. Furthermore, there are no disposal costs for the insulating material.