30 years of B.T. innovation GmbH in Magdeburg

The company B.T. innovation GmbH and its workforce have stood for the development of pioneering products for the construction and precast industry for many years. A look here back over the by now 30-year company history:

In September 1991, following studies in the field of construction engineering and business administration, Felix von Limburg, managing shareholder of B.T. innovation GmbH (BT), came to Magdeburg, Germany, to build up a business for special building products.At that time, the product line included spacers made of plastic and fibrous concrete, which he personally delivered in his box van. Owing to the building boom following unification of Germany, business got off to a very good start, with the result that he was soon able to hire a first employee and rent a garage for storage in the neighborhood.

The 1990s – a decade full of changes

The year 1996 was for BT a year full of changes in several ways. For one, the company moved to Ebendorferstrasse 19/20 in Magdeburg and, secondly, the entrepreneur Felix von Limburg decided to find the company B.T. Baubedarf Magdeburg GmbH. The objective was to further develop his building products trade with limited product portfolio into an independent wholesale and foreign trade company in order to counter the beginning stagnation in the building trades and increasingly intense competition. BT stands for building and technology – i.e., for technical products for all aspects of building. With an extended, reorganized product range, the company was able to master the difficult times in the industry.

When, at the end of the 1990s, there were signs that increasing market transparency at the beginning of the Internet age could make classic sales of consumable goods for building difficult, Felix von Limburg and his staff began not only to sell products and services, but changed their focus to in-house patent-protected developments for an innovative construction industry. Their first patent was applied for reusable and flexible formwork for round concrete elements (Syflex).

In 2004, not least to emphasize this objective in the context of technological progress, B.T. Baubedarf Magdeburg GmbH was renamed B.T. innovation GmbH. This change in company name documents not only the innovative character of the new product world and technologies, but also the extended customer base. Because in the meantime, BT had also won customers from the precast industry and business had become internationalized. In 2005, in order to be able also to support customers from the precast industry with consulting services, BT broadened its performance spectrum and knowhow by taking over the company BetoRatio GmbH. Ever since, it has offered consulting, leading up to implementation of complete system solutions for production of precast elements. In the course of the years, investors and owners of precast plants in Germany and abroad have been provided with consultation for erection and optimization of their production facilities.

Final breakthrough with formwork magnet

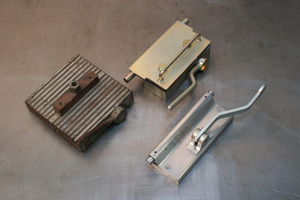

With the MagFly AP formwork magnet, final breakthrough succeeded as supplier of products of high technical quality for the precast industry, as the BT staff “stood the magnets on their feet” to ensure ergonomic ways of working. After that, other products were added, such as the BT turnbuckle – a dry screw connection for durable connection of precast elements, and the ThermoPin – a composite anchor made of glassfiber-reinforced plastic (GRP) for sandwich walls and core-insulated double walls as well as sealing materials, some of which also glue under water.

During 2012, the company moved into its new business premises: the company headquarters today, in Sudenburger Wuhne, in Magdeburg. There, the new administration building was erected of precast elements during 2013 – 2014, using the BT turnbuckle and the ThermoPin, which serves ever since as reference project for demonstrating the efficiency benefits that can be gained through the use of BT products. In parallel, the Low-Cost House was developed. The house, measuring 36 square meters, is made of precast elements that can be erected within two hours. Central to the concept is the butterfly battery that was especially developed for efficient production of the precast elements which are screwed to each other with the BT turnbuckle. The creation of affordable housing is a project that lies at the heart of Felix von Limburg and also influences the company’s product development. In 2017, MAX-truder GmbH was founded to supplement the formwork products for precast element production, which has taken over parts of the fixed and current assets of the insolvent Weiler Maschinen- und Anlagenbau GmbH to enable it to offer machinery and equipment for production of prestressed precast elements “Made in Germany” also in the future.

In order to offer the workforce of about 75 in the company group a perspective for the next 30 years, BT has now formulated a corporate strategy until 2030 to define the guideposts for long-term development. In essence, this is about establishing system solutions in the market for continuously promoting modular-serial building and reacting with innovative solutions to the various requirements of customers in the future as well.

CONTACT:

B.T. innovation GmbH

Sudenburger Wuhne 60

39116 Magdeburg/Germany

+49 391 7352-0