90 years of progress and tradition in mechanical engineering

Paul Maschinenfabrik GmbH & Co. KG celebrates its 90th anniversary this year. What in 1925 began as a metalworking shop evolved long ago into an internationally active company in the three business sectors: circular sawing technology, prestressing technology, and strand lifting technology. The quality of the family business in Upper Swabia in Germany is held in high esteem worldwide, as confirmed by its many projects. These include over-dimensioned multi-blade circular saws for ripping apart large-area slabs, circular edgers in use for decades, prestressing technology for reconstruction of the famous Dresdner Frauenkirche church, CFK lamellas for stabilizing an elevated highway, and state-of-art prestressing equipment for concrete plants.

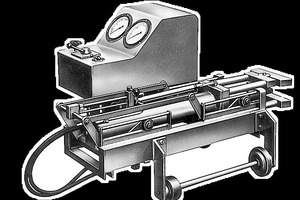

The founder of the company, Max Paul, started out in his father’s business in the German city of Dürmentingen, at first in production of special machines for manufacturing whips. After World War II, his two sons Berthold and Odilo Paul joined the company. Together they developed and built the double-edging circular saw in 1948, which became an instant success. In the 1950s, their product range of the circular saw technology grew continuously.

Prestressing technology as additional mainstay

With the first equipment and machinery for prestressed concrete production, the second main area of activity of the company Paul, prestressing technology, was added. The company continuously enlarged its production site in Dürmentingen and, in the mid-1970s, moved part of its production to Riedlingen, where it has continued until today. In the 1980s, CNC technology began to gain increasing significance: CNC-controlled cross-cut systems and optimizing edgers enabled automated production processes in industrial wood processing, as well as button-heading machines and prestressing robots in production of prestressed railroad sleepers. In 2000, the company Paul, which needed more space, moved production from the site in the inner city to a new industrial estate in Dürmentingen and soon, ten years later, enlarged the production site once again.

In 2012, with the professional market entry into strand lifting technology, the company’s third mainstay was added – one in which its design engineers had been able to gain much experience during previous years. In 2014, Paul took over the company Reinhardt Maschinenbau and carries on under the Reinhardt brand in the plant in Rottweil-Neukirch, Germany.

Today, the third generation heads the company

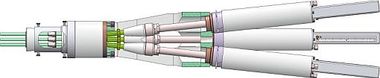

Today, the third generation of company management is headed by Barbara Hering and Werner Paul. With its advanced technology, Paul satisfies the most exacting requirements of its customers. The comprehensive product portfolio includes single-wire to multi-wire stressing jacks with suitable hydraulic units for tensioning at the construction site, abutments for prestressing beds, as well as tension-release cylinders for in-plant manufacture of structural components. Numerous accessories for recording, measuring, tensioning-wire handling, and a comprehensive offer of clamp fasteners round off the product range. With highly professional planning and consultation, Paul offers not only products, but also complete solutions tailored to customers’ requirements. The high quality and value stability of the products, as well as first-rate service, are the basis for long-term collaboration in partnership with many customers around the world.