Product range for tensioning stepped anchors extended

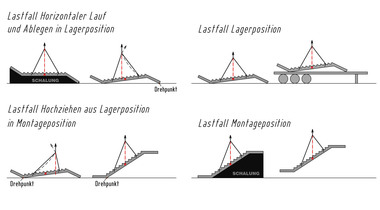

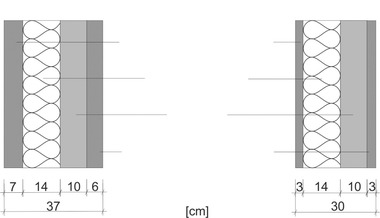

Stepped anchors are a special type of compression anchor. Both types are used as ground anchors in various applications, for example, where walls or tunnel slabs have to be tensioned against the ground. The two types differ in that the individual strands of a stepped anchor are not of equal length, but of different lengths. The load transmission areas of the individual strands are staggered successively in the ground, ensuring in this way uniform load transmission into the subsoil. If the ground is no longer capable of supporting the load of a standard compression anchor, stepped anchors are used.

In practice, stepped anchors are often tensioned with single-wire stressing jacks to ensure equal tension in all individual strands. Alternative processes using multi-strand pressing jacks apply different stresses. Simultaneous threading of the strands and adjusting the presses to different anchor types is a relatively complex procedure.

Two types of stepped stressing jacks

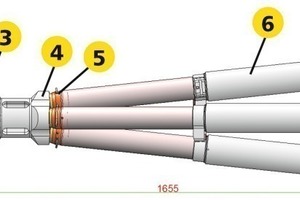

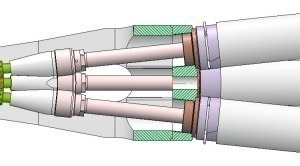

Paul Maschinenfabrik, as specialist for prestressed concrete technology, has already gained valuable experience with stepped stressing jacks in the past, has optimized the process and now offers two types of jacks. Both types are used with a special support seat and individually applied stressing jacks, which are hydraulically connected to each other.

This process offers several advantages: For example: identical individual stressing jacks can be modularly combined with support seats for 4 to 7 strands (or more). For anchors with different strand arrangements (hole pattern) or different number of strands, only the exchange parts in the support seat need to be exchanged. Comparatively simpler and lighter weight jacks can be easily exchanged, for example for maintenance work.

High stressing force achieved with simple assembly

Assembly is very easy in that the support seat is mounted on the anchor and the individual stressing jacks threaded onto the strand. The individual stressing jacks are, moreover, connected with the support seat via rapid action coupling to ensure that all of the individual presses stay in place during the test cycle. Alternatively, the use of a single press barrel (wedge-seating force 120 kN, stroke 20 mm, length 150 mm) for hydraulic wedge-seating is possible. This reduces wedge-seating loss and has already been successfully used in other applications.

In addition, the elongation distance on every stressing jack is optically checked via an integrated ruler; use of an electronic distance measuring system is also possible. The maximum stressing force is 240 kN, which is optimal for a strand 0.6“, with a deflection of 6°.