Anchor channels for the Jade-Weser-Port

The Jade-Weser-Port in the coastal city of Wilhelmshaven is regarded in Germany as a project of the century. Precast concrete elements were fixed on the seabed with anchor channels from Jordahl.

The only tide-independent deep-water container port in Germany opened for business in the fall of 2012 in Wilhelmshaven, following a 7-year planning, approval and tendering phase, and a construction time of four and a half years.

With an investment of EUR 480 million (total investment volume around EUR 950 million), a quay of 1,725 m length was created. Sand had to be piled onto the surrounding embankments and an area of 360 ha reclaimed, to the most part by spraying on 46 million m3 of sand.

For the quay of 1.7 km length, a steel sheet pile wall had been specified, whose individual piles were driven 20 m deep into the seabed. The individual sheet piles are interconnected with so-called interlocks to create a sand-tight area. Early in 2012, declutching on the interlocks occurred – at first only in isolated places, later in larger numbers. Damage of that kind is not rare with large-scale sheet piling projects. When the interlocks become declutched, the sand behind them can leak out.

Leaky sheet piling

Individual damages that had occurred along the first 1,000 m of the quay were initially filled with concrete from the shore and welded below water from the outside. With this method, however, the tight construction schedule could not have been met, given the extensive damages that had occurred along the entire quay. The Joint Venture decided therefore on a radical measure, i.e. to rehabilitate the affected sections of the quay.

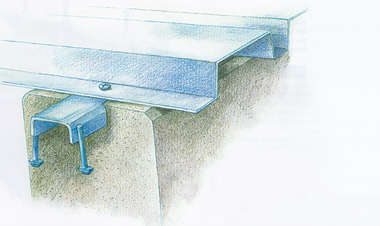

In the damage area, 707 precast concrete components were installed as permanent formwork in front of the original sheet piling wall and anchored to fender pipes. The spaces in-between were filled with underwater concrete. Two special-purpose pontoons, supported by sonar technology, positioned the precast components with a weighing from 4 to 5 t.

Precast components on the seabed

In the first section, the bottommost row of the precast components could be placed directly on the harbor floor. The situation for the remaining 750 m of the quay, however, was different. Due to the unfavorable soil conditions, an additional concrete toe sheet piling wall had to be erected on the harbor bed. Between this and the steel sheet piling wall a total of 640 precast components were subsequently installed. For fixing the lower rows of precast to the new toe sheet piling wall, ties were to be provided, which were to be bolted to anchor channels in the precast concrete components.

An extremely critical factor for the repair was the time and, accordingly, the delivery time of the precast components, the required anchor channels, and the special bolts.

“The second construction section of the quay had to be completed by 30 November 2012,” explained Dipl.-Ing. Martin Hanneken, the site manager for the repair of the quay at the lead consortium, Johann Bunte. The initially commissioned supplier of the anchor channels was unable to guarantee the deadline of two weeks upon receipt of the order so that Jordahl GmbH was awarded the contract, following a trial delivery the company had provided on a short-term basis.

Not from stock

Anchor channels with the specified dimensions are not held in stock, but manufactured to the customer’s specifications. Jordahl had to react flexibly and fast. “The contract was awarded on a Friday. The process schedule for the production was drawn up over the weekend and production started on Monday,” said Markus Bohne, construction designer at J&P Bautechnik Vertriebs GmbH, Jordahl’s sales organization.

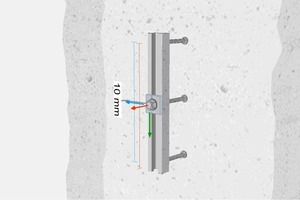

The specialist for fastening technology based in Berlin supplied 1,200 m of Jordahl anchor channels of type JTA W72/48 fv CE and 2,750 special-purpose bolts of type JA in M20 as well as M24 in lengths between 75 and 150 mm. The Jordahl anchor channels of type JTA are hot-rolled channels with reinforced lips for high tightening torques. Reinforcement of the channel lips enables transmission of especially high loads. The channels are available in five different cross-sections from 40 x 22 mm to 78 x 48, which JWP uses as well, and in various lengths up to 6 m.

Jordahl anchor channels are available optionally in stainless steel or hot dip galvanized steel. In this special case the more economical hot dip galvanized variety could be used. The thickness of the zinc coating on the anchor channels ensures the necessary corrosion protection for the temporary construction. The channels, together with the ties, fixed the precast concrete components to each other until the underwater concrete between the toe sheet piling and the precast components had hardened.