“Bahnstadt” project with Isokorb and Tronsole

Until 2022, the “Bahnstadt” residential development will be completed to create the world’s largest array of passive houses on the site of the former Heidelberg cargo station, which is situated immediately behind the main station area. Upon completion, the new neighborhood will be the home to 5,000 inhabitants whilst also providing the basis for creating about 7,000 jobs. Construction began in 2008, and about one third of one of the largest projects currently underway in Germany has already been completed. The project’s total construction cost amounts to about 2 billion euros.

Above-average construction costs are due to the premium quality of the materials used, but also result from the passive-house design that includes triple glazing, controlled ventilation with heat recovery and a very efficient thermal insulation of the building envelope. Inhabitants thus enjoy superior comfort, a healthy living environment and exceedingly low heating costs, which will pay back the additional investment over the course of only a few years. In line with the passive-house concept, the buildings use their internal heat gains to produce the lion’s share of the required heat; the small remainder is supplied via the district heating network.

Isokorb elements

ensure thermal break

One of the many projects that this city-center residential development encompasses is the Pfaffengrunder Plateau group of buildings, which is centrally located in Quarter W4. With a few exceptions, these ten buildings are arranged alongside the site perimeter. They were designed by Gramlich Architekten, Stuttgart, and built by Dreßler Bau GmbH, Rastatt. This project includes 77 rental apartments and 39 condominiums that extend over three to six stories; some of the buildings have an additional, recessed story. All of these apartments feature a large balcony or (roof) terrace; the façade has been fitted with a composite thermal insulation system.

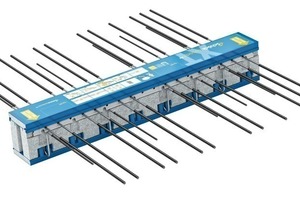

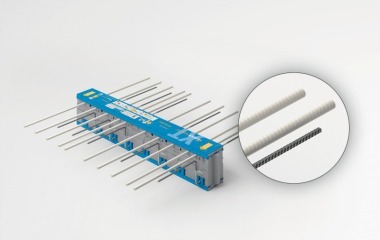

Schöck Isokorb XT elements, which are certified to the passive-house standard, connect supported and unsupported, projecting balconies to the structural framework. In total, 432 of these load-bearing insulation elements were used to transfer uniaxial bending moments and shear loads from the balcony slabs to the reinforced-concrete floors whilst also eliminating the thermal bridge that would otherwise be created at this connecting point. Depending on the specific application, Isokorb QPXT elements were used for point-loaded balconies that rest on reinforced-concrete supports whereas Isokorb KXT products were installed for the projecting balconies simultaneously with rebar placement and casting of the floor slabs.

Tronsole provides

impact noise insulation

Yet multi-story construction is not only concerned with efficient thermal insulation but also requires the elimination of sound bridges when installing staircases. The Pfaffengrunder Plateau residential project uses more than 200 Schöck Tronsole elements of the AZ type to provide a reliable impact sound break between the cast-in-place landings and the staircase wall.

Furthermore, almost 350 Schöck SLD dowels transfer shear loads into expansion joints without having to install the usual beams or corbels.

As a subproject of the “Bahnstadt Heidelberg” development, this group of passive houses received the “Passive House Award 2014”. The Schöck elements used for this project have made a major contribution to this achievement.