Boost efficiency with laser projection – plus a new feature by LAP

Excessive manual work tasks can cause bottlenecks and cause lower availability levels in production. Laser projection systems apply a significant boost in efficiency in precast concrete plants. The integration of laser systems results in significantly reduced set-up and processing times at the work stations, thus increasing component quality and plant productivity while keeping cost low. Still, even further potential can be unlocked. A new feature added to these systems opens up additional new possibilities for quality assurance.

Manufacturers of precast concrete elements are faced with the challenge to produce large quantities of uniform high quality at an increasingly faster rate. At the same time, the elements are becoming increasingly complex. In order to keep pace with the ever-growing complexity and to meet the demand for high-quality products and cycle times, more and more plants worldwide are implementing laser projection systems. These systems eliminate the need for manual measuring with a tape measure and optimize efficiency throughout the entire production cycle.

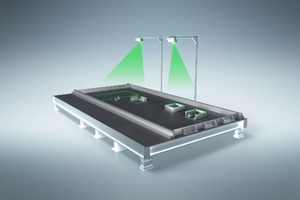

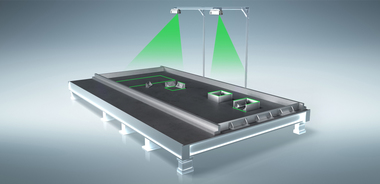

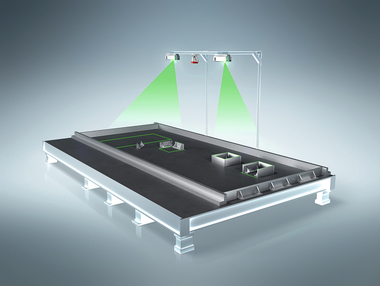

Laser projection systems are used at various workstations, ranging from placement of formwork, positioning of components and display of cut-outs to placing reinforcements. Finally, they also check the presence, correct positioning and orientation of all elements before filling with concrete. This is especially relevant for double wall production in order to ensure that, on the one hand, each wall fits properly to the other half and that, on the other hand, reinforcing bars or mounting parts do not collide when joining.

Based on CAD data, CAD-Pro laser projection systems display the precise location of all elements. In a typical application, they project the outlines of cut-outs onto a fixed table/ flat bed/ deck or a carousel pallet. The PRO-Soft software controls the entire workflow: from importing projection data from CAD programs, calibration and visualization of projection steps, to documentation. The software also takes into account different heights of the components and visually compensates for such differences. The software is compatible with all known master computer systems (such as Unitechnik, RIB SAA, Progress etc.) with common data formats such as DXF, HPGL, Unitechnik 4.0-7.0 and UXML. With all elements placed precisely on pallets or tables/ beds/ decks laser projection also contributes to a constant product quality. Compliance with production tolerances down to millimeter accuracy can ultimately prevent claims.

Outlook: Camera systems added to existing or new laser projection systems from LAP can generate additional benefits. The DTEC-Pro camera system allows to visually check the positions of all elements and detect positioning errors before pouring the concrete. In addition, camera live images can be stored in the database for documentation. These functions further enhance process reliability and help assure component quality.