Laser projection systems for the precast industry – Benefits and opportunities

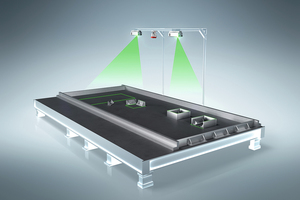

Integrating laser projection systems already provides measurable benefits in precast element production, such as speeding up the process and avoiding errors and, consequently, rejects. The systems’ key advantage over manual measuring methods is that they enable continuous, software-assisted digital workflows from CAD data to quality control and manufacturing documentation.

Increases in quality and efficiency through digital work plans benefit

all work stations, including formwork placement, the positioning of embedded parts, the display of cutouts, and rebar installation. In addition, laser projection systems help checking if all elements are included and if their positioning and orientation is accurate prior to concrete pouring. This is particularly relevant for double wall production to ensure that, on the one hand, each wall fits properly to its counterpart and that, on the other hand, rebar or embedded parts do not collide during joining.

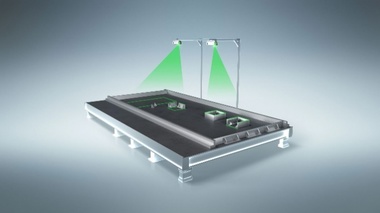

Yet there is even more potential to be unlocked: Camera systems

integrated in LAP laser projection systems enhance process

reliability in precast plants and provide additional support in quality control.

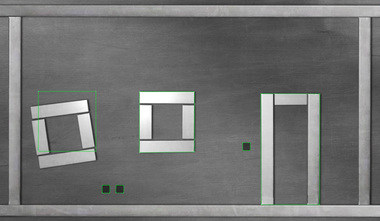

LAP’s DTEC-PRO camera system generates live images that can be saved in a database in order to document the manufacturing process. The correct positions of all elements can thus be checked, and possible positioning errors can be detected before pouring the concrete. Even drawn-in laser projection outlines can be superimposed on the images. This feature makes it possible to document the actual status and verify how work was done according to the projected contours. Users thus receive digital proof that all work steps have been completed correctly.