Interview: „Innovative laser projection technology for the concrete industry“

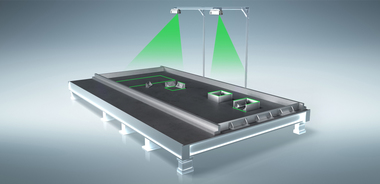

LAP has been developing and manufacturing laser projection systems for the global concrete industry for 20 years and is continuously driving the technology development process in order to meet customer requirements with innovative solutions. On the occasion of its 40th company anniversary, LAP presents the new CAD-PRO Xpert (BFT International reported). These alone are several occasions for an interview with Max Mandt-Merck, industry expert for the concrete industry at LAP.

BFT International: Mr. Mandt-Merck, LAP has been an expert in laser technology for 40 years and partner of the concrete industry for two decades. What distinguishes LAP, apart from the many years of experience in laser technology?

M. Mandt-Merck: I think there are three factors: experience, innovation and customer orientation. We have been at the fore of technology development for 40 years. LAP developed the first laser projectors for high-quality standards in aerospace. We apply this approach to all our products and industries. Close proximity to the customer is important to us here for developing and continuously improving hardware and software to optimally keep abreast of increasing industry-specific requirements. Our focus is always on the user-friendliness of the products. Our many years of industrial knowhow is here of great help. Our laser projection systems are today successfully in operation in more than 30 countries and in the most diverse industries – including the wind and automobile sectors, composite manufacture and timber-frame house construction – and, since the early 2000s, in precast element production as well. That fills us with a little pride and encourages us to continuously deliver top performance.

BFT International: What is today’s role of laser projection in precast element construction?

M. Mandt-Merck: Laser projection technology in modern productions is today state-of-the-art. Growing cost pressure and relentlessly demanding requirements make this technology an indispensable instrument for process optimization and quality assurance. Precast elements must correspond 100% to specifications. By means of laser projection, personnel in production can position formwork, reinforcement and other elements reliably, faster and with great precision. This results in fewer errors, improved quality and, because processes are in general accelerated and simplified, in more efficiency. Some of our customers report time savings of 70 % and more. This technology supports the construction industry by the following: adhering to precision, speeding up production and process flows and, in this way, staying competitive. This is, we believe, currently more crucial than ever.

BFT International: How do you assess the current market situation in the construction industry and how does LAP, as system supplier, react to it?

M. Mandt-Merck: We are also aware of the current challenges that the construction industry is facing in some regions. We notice, however, that many of our customers use this time, or are regretfully even forced to use it, to rethink and to reorganize their corporate structures and production systems. In response, we constantly optimize our offers and solutions in order to optimally support our valued customers and continue to be their reliable partner. After all, not every manufacturer of concrete elements has a well-established niche that ensures constant high production capacity utilization. But we are optimistic that this economic situation will bottom out. In the meantime, we have intensively worked on further development of our production system and we are especially pleased to be able to present our new CAD-PRO Xpert to the precast industry.

BFT International: What are the advantages of the new laser projection system for precast plants?

M. Mandt-Merck: CAD-PRO Xpert has been developed with a new high-performance technology platform which offers even greater precision and laser line quality. We have, again, significantly improved visibility of the laser lines. This is a genuine milestone, especially from projection distances of more than ten meters. Additionally, LAP has been able to receive a laser class 2 certification with the CAD-PRO Xpert through additional sensors, at up to 14mW laser power! And if more is required, you can get as high as 60mW in laser class 3B. This greatly reduces the time and effort required by precast plants and their otherwise needed laser safety measures. The device can, moreover, be optionally fitted with a second laser source. This feature provides additional fail-safe protection. In summary: we offer the most advanced laser technology, paired with user-friendly software, fast Gigabit-Ethernet data transfer and simple integrating ability. We are convinced: our new laser projector once again sets new standards.

BFT International: What resonance do you expect?

M. Mandt-Merck: Customers to whom we demonstrated the system were highly interested not only because it improves process reliability, efficiency and the quality of their production, but also enhances work ergonomics. Laser technology optimally supports experienced and often long-serving employees in their day-to-day work and in this way upgrades workplaces. For all these reasons, we see great potential for broad market acceptance and successful implementation in the most diverse sectors of industry.

BFT International: And, finally: to what may the concrete industry especially look forward?

M. Mandt-Merck: On the occasion of our 40th company anniversary, we also want to say thank you to our customers. For our existing customers in the concrete industry, we have, for example, developed attractive offers for regular maintenance. For all those interested in the new CAD-PRO Xpert, we have also thought about a promotion that will especially please regular BFT readers ...

BFT International: Mr. Mandt-Merck, we thank you for this conversation, and we wish you continued success.

CONTACT

LAP GmbH Laser Applikationen

Zeppelinstr. 23

21337 Lüneburg/Germany

+49 4131 9511-95