Energy efficiency with prefabricated floor construction

The new Heidger Institute is located in the German community of Osann Monzel, on the River Mosel in the midst of vineyards. The new facilities of the internationally known Institute for Quality Management and Quality Assurance for Wine and Liquors have proved impressive owing to optimization of their characteristics for their intended use, and for their degree of sustainability and energy efficiency.

The reinforced-concrete skeleton structure, three stories high, was erected on a footprint of 800 m². Only a small number of columns and walls were required to support the flat slabs with prefabricated floor elements. The open-spaced rooms with a floor space of around 360 m² each, arranged on both sides of the access zone of the building, require only two central columns. This enables flexible arrangement of the individual rooms, as well as their future alteration.

Multifunctional floor construction

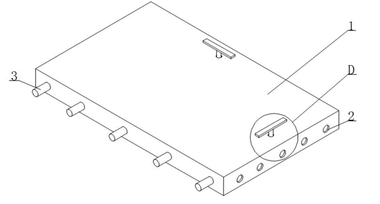

The special feature here lies in the concept and implementation of the floor construction. For this construction project, a sandwich cross-section was used instead of the customary full cross-section. This consists of two thin loadbearing shells; the shells are connected by individual ribs, with a hollow space between the ribs.

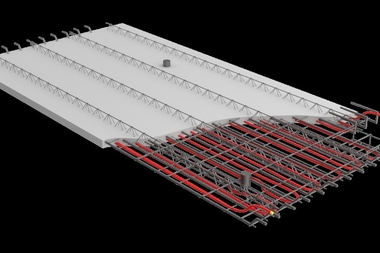

This cross-section saves material and weight. It is furthermore light and yet stable and is therefore suitable for large spans. Spans of up to 10 m are possible with a floor thickness of only 40 cm. The individual floor elements are manufactured in the precast plant, complete with the shells. They are erected on site and connected with beams that are topped to the required height with in-situ concrete, to form a loadbearing construction. The high-strength, prestressed reinforcement in the flush beams makes it possible to implement the thin floor construction as flat slab.

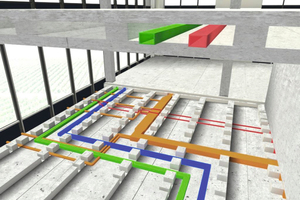

The Ceiltech floor construction, aside from the savings in material and weight, has additional advantages: The components of the building services, which are usually arranged below the floor, can with this innovative construction be integrated into the cross-section of the floor. This leaves the entire hollow space in the floor for installation of the ventilation and electrical systems. To enable piping to be installed in all directions, also through the ribs, large openings are necessary in the webs. Inspection access openings in the upper shell enables monitoring of the condition of the piping.

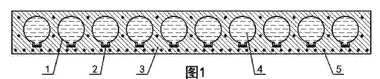

The piping for heating and cooling are already embedded in the concrete of the lower shell in the plant. This makes gentle climate control by means of radiation possible and ensures a very comfortable indoor climate, free from drafts. Here, unlike conventional climate control, all surrounding walls are uniformly heated and/or cooled – instead of the air.

The inlet temperatures, which provide the thermal energy, can be kept at a very low level, thanks to the large open floor surface. This enables extremely energy-efficient supply by heat pumps.

New connection technology

These prefabricated floor elements satisfy the prerequisites for cost-efficient energy distribution in the building. The required energy generation util-izes warmth from the earth in the form of geothermal energy. Heating and cooling with renewable energy are not only highly sustainable, but also extremely economical. Geothermal piping down to a depth of 130 m supply a nearly uniform temperature of 10.0 to 13.0 oC all year, which allows the heat pumps to operate very efficiently. To supply the building with heat, the heat pumps must increase the temperature to a level of around 30 oC. Cooling takes place at no cost, without the use of a heat pump, since the low temperatures from the ground are fed, via a heat exchanger, directly into the tube banks installed in the floor slabs. This so-called passive cooling is especially efficient and economical.

The high efficiency of the climate control systems is ensured by the various storage possibilities of all participating elements. The ground stores the energy from the summer for use during the winter. The mechanical buffer storage unit ensures a uniform supply with cold or heat from load peaks. The concrete mass of the floor slabs is used for additional energy storage as well in order to absorb thermal peaks. All of this ensures uniform, constant, and not least cost-efficient operation of the building technical systems.