ComTec residual concrete recycling system for Amos

Albert Amos GmbH & Co. KG is a company with 80 years of tradition that is headquartered in Brackenheim, near Heilbronn in Germany. With a workforce of 160, Amos is active in the sectors of building construction and underground and road construction as well as project development and turn-key jobs. In addition, the company operates its own ready-mix concrete plant and delivers concrete in all grades. The vehicle fleet consists of three truck mixers and two concrete pumps.

To solve the existing disposal problems posed by the residual concrete and the wash water in the Güglingen plant, the decision was taken – among other reasons, as a result of the ecological convictions expected of a modern company – to invest in a residual concrete recycling plant.

Delivery of the plant had been preceded by an appropriate planning phase, which took consideration of the local conditions.

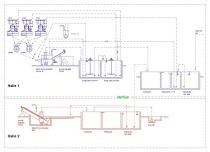

Com Tec 20 trough system

To enable quick disposal of the residual concrete quantities, the company decided on the ComTec trough system. The machine was installed below floor level to compensate for the existing difference in height. The advantage here is that the charging hopper is on floor level. This also enables the truck mixers to wash out concrete pumps at the same hopper, without requiring an additional system. A helical conveyor ensures ideal discharge of the washed-out materials.

The ComTec 20 plant system that was delivered has a recycling capacity of 20 m3/h and is fully equipped, including a recycling water treatment function. The truck mixer is filled with recycling water, after which the residual concrete is discharged directly through the charging hopper into the machine. Here, the solids > 0.2 mm are washed out and discharged. The water containing fines < 0.2 mm flows into a water drain and an agitator basin. The agitator in the basin keeps the fines in the residual water in motion by stirring to prevent the fines from settling. The water containing the fines is returned to the mixing process.

The plant system is furthermore equipped with a sand and gravel separation function to ensure an enhanced quality of the washed-out solids during separation.

The Bibko ComTec system contains a patented storage system, with 1,600 successful applications, that was placed outside the water bath to prolong service life.