1,500th residual concrete recycling plant delivered

The environmental engineering and consulting company Bibko Umwelttechnik und Beratung GmbH recently delivered the 1,500th residual concrete recycling plant in its company history.

The plant was set up and installed in the ready-mixed concrete plant Fleischmann & Zankl, which is part of the Zankl Bau Group, a family-run construction company. What began with founding of a company by the construction materials dealer Josef Zankl fifty years ago, now continues with the production of concretes for the building and construction industry, the civil engineering sector, and agricultural building.

ComTec-System with a recycling capacity of 20 m3/h

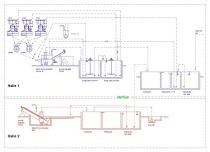

Bibko was awarded a contract to design and deliver a ComTec residual concrete recycling plant. The customer decided to install the plant on raised terrain, which allows the advantage of locating the feed chute on ground level. This enables the concrete pumps to wash out at their own feed chute without the need for an additional system for washing out these pumps. On a separate stationary funnel, this allows washing out two truck mixers at the same time. The helical washout unit, 3m long, ensures ideal discharge of the washed-out material.

The ComTec 20 plant system offers a recycling capacity of 20 m3/h and is completely outfitted with a recycling water-conditioning unit. The mix is transported from the funnel directly to the machine, where solids > 0.2 mm are effectively washed out and discharged. The water containing the fines < 0.2 mm goes to an agitator basin. The basin is fitted with an agitator that keeps the fine solids in suspension by cyclic stirring. The water containing the fines is returned to the mixing process. The Bibko ComTec system features a patented bearing, proven now in 1,500 ComTex plants, which is positioned outside the water bath and offers a higher service life.

Recycling systems also for the precast concrete industry

Recycling systems are also used in the precast concrete and concrete products industry. If a ready-mixed concrete plant focuses primarily on recycling residual concrete, the emphasis will primarily be on the treatment of excess wash water. This water cannot be directly returned to the mixing process and is purified so that it is subsequently available for reutilization in the production process. Following appropriate treatment, the purified water can also be drained into the public sewer system.

The sludge that is produced during treatment is, if at all possible, also once again used in the mixing process so as to create a closed circuit. If the sludge quantity that has been produced is more than can be used in the mixing process, the system can be additionally fitted with a chamber filter press.