Specialist in residual concrete and wash water treatment

The Bibko Company is a specialist in the field of residual concrete and wash water treatment in the ready-mixed concrete, precast concrete and concrete products industries. Another focus is on the conception of recycling systems for the treatment of residual mortar and residual anhydrite as well as lightweight concretes. This is ensured by an expierenced, competent team of professionals with over 40 years of experience in the production of more than 2,100 realized plants. An individual solution designed to the specific needs of the customer also belongs to the service.

At Bauma in Munich, booth FS 906A/3, they will present current systems for residual concrete recycling and purification of residual water and water containing cement.

Economical aspect: The investment in a recycling system for residual concrete will already result in measurable savings after a short time owing to the material cycle installed. These are shown above all by savings in disposal site costs, water and the recovery of aggregates. Apart from the mere economical aspect, a customized recycling solution is also leading to a holistic concept for materials and water management in the concrete plant.

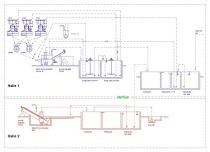

Recycling systems: A recycling system is a closed loop system. Apart from the recovery of the constituents contained in the residual concrete, the residual water is also fully used in the mixing plant. It contains fine particles and cement particles. Any material that has to be disposed is avoided by this system. Therefore, it represents a closed systems. Residual water purification by means of chamber filter presses: An optimum purification of residual water and an efficient possibility to filter fine particles out of the water.

The following Bibko systems will be exhibited at Bauma:

ComTec

The Bibko ComTec features an excellent recycling result and a completely galvanized aluminum cover. The system is washing out the residual concrete so that sand and gravel, being free of cement, can be reused. The driver of the mixer truck backs his vehicle against the receiving hopper and turns the swiveling washing jib (as an option) over the feeding hopper of the truck. By activating the button „washing jib“, about 400 to 500 l of recycled water are fed out of the recycling water basin into the truck mixer for using the same to rinse the mixer drum. Simultaneous to the intake of water, the washing out system is set from its clock cycle (impulse = 5 min/break = 15 min) to its washing cycle (impulse 25 min). Every further activation of the washing jib is automatially setting the washing impluse to additional 25 min (any time can be set).

After thoroughly rinsing the mixer truck, the free-flowing material is fed into the receiving hopper of the washing system. The internal helix, fitted with plastic shovels and plastic paddles, is moving the sand and gravel towards the helical conveyor and, in this process, is cleaning the interior walls of the trough washing unit by continuous stripping. At the same time, fresh water or recycled water (optionally) are fed to the trough washer from side of the helical conveyor so that washing out is performed according to the counter current principle. The surplus water and the finest fractions under 0.2 mm are passed into the recycling water basin using a special discharge system.

Bibko „ClearPress“ chamber filter press

To purify the surplus residual water in a professional manner, there is the possibility to supplement the recycling system for residual concrete by the chamber filter press „ClearPress“. The process is running automatically what saves the operator a manual operation as far as possible. So, if the water level in the agitator basin rises above a value previously set by the customer, the ClearPress starts automatically in order to bring the filling level to the previously determined level.

The recycling water containing the fine particles is pumped with increased pressure into the ClearPress using a compressed air diaphragm pump, thus it is purifying the recycling water. The fine particles contained in the water are pressed by the corresponding filter plates, which are covered with special filter cloths, to form a solid filter cake. Afterwards, the press opens automatically and ejects the material by vibration. The filter cake resulting from the water purification process can simply be reused, e.g., as recycled material in road construction. The purified water itself can be returned to the production process.

Both the chamber filter press and the recycling systems can be equipped with additional attachments, such as the density measurement system or the pH neutralizaiton system. The Bibko chamber filter presses are offered in different sizes and versions and are adaptable to all common recycling systems for residual concrete.

CONTACT

Bibko Umwelt- und Reinigungstechnik GmbH

Steinbeisstr. 1+2

71717 Beilstein/Germany

+49 7062 9264-0