Conflex: Higher distribution speed, greater plant productivity

There are many compelling arguments in favor of operating a central batching and mixing plant that ensures concrete supply. To name but a few: a more streamlined logistics system behind receiving incoming materials, aggregates, cement etc.; production integrity: it becomes more economical to build stand-by mixing/batching capacity into the plant; a common proc-ess control system that makes it economical to have systems that are capable of linking up to central ERP systems, the laboratory etc. In short, this plant design results in a better management and control of production, and higher quality and traceability, whilst providing a single point of connection of services (power, water, recycling system etc.).

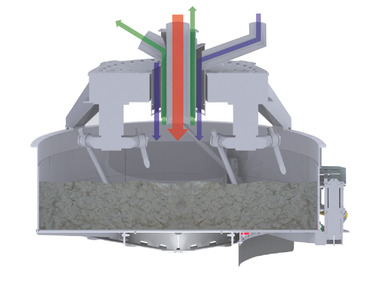

To take advantage of the benefits of a centralized batching and mixing plant, it is crucial to get the concrete to the point of use: to the casting molds, the extruder for hollow-core production, the paver machine, the pipe machine or any other production equipment. Furthermore, in many production facilities, the concrete needs to be conveyed to several points simultaneously.

A little history

The Conflex bucket conveyor concrete distribution system was launched on the market as early as in 2001. It has since been updated many times to make use of the latest available technology.

When introduced, the system was nothing short of a minor revolution, and it is still unrivaled. However, the system available at the time of its launch was a slow system that usually included just a single conveyor suspended from a single drive-rail, or a similar dual system running on steel wheels in two rails. Either of these systems was equipped with a electro-mechanical drive.

The challenge of the single-conveyor system was primarily its safety, namely how to ensure that the area below the bucket conveyor became a “no-risk area”. If the area below the bucket conveyor tracks were classified as a “hazardous area”, this would exclude it from becoming productive whilst being inaccessible for staff and thus for the placing of molds, casting beds etc. In other words, this would be a “non-profit-generating” area within the available production space.

High speed, inclines of 20%

The Conflex design addresses this issue by providing a system in which the bucket runs on top of the rails and by allowing the frame of the bucket to extend beyond the wheel base, thus ensuring that even in the worst case (a breakdown of a wheel axle), the bucket would not pose a hazard to staff working underneath.

The conventional bucket conveyor design includes steel wheels running on steel rails, which makes it impossible for such conveyors to run at high speeds. Such systems are usually restricted to a maximum speed of 2.5 or 3 m/s − not because higher speeds are not possible but because it is impossible to brake within the required, practically feasible distance.

For a full round trip, such as in hollow-core production (filling at mixer, drive to station, discharge at station, return to mixer), this difference could easily be equivalent to the difference of being able to serve an extruder at a distance of 100 or 150 m without disrupting concrete feed to the extruder in order to ensure productivity and quality.

The Conflex system solves this problem by using rubber wheels that achieve the required friction for both acceleration and deceleration purposes. The added benefit of rubber wheels is their ability to run at high inclines. The Conflex system makes it possible to run at a 20 % incline, thus providing ample freedom to integrate the system into existing facilities or to place the batching and mixing plant at an economical height.

High-pressure washing system

The growing use of self-compacting concrete has made distribution speed an increasingly important factor. Due to the fact that the casting time of self-compacting concrete is reduced significantly, a process that used to take eight hours can now be completed within three to four hours, or is even shorter in some cases. However, it is very common to not capitalize on the benefits of using the more expensive self-compacting concrete because the time saved in the casting proc-ess is wasted again due to the distribution bottleneck.

The control of the Conflex distribution system is fully integrated into the Skakomat 600 process control computer (although features are available to also integrate the Conflex into other makes of control systems). This permits the provision of “concrete on tap”, i.e. the type and amount of concrete is controlled from the point of use rather from a central point, which is usually the mixing plant operator.

The Conflex system can be supplied with all the usual add-ons required in a modern and highly productive manufacturing environment. Most importantly, these benefits include automatic high-pressure washing systems (with a water pressure of 170 bar and a washing cycle of approx. three to four minutes), which makes the system a good choice for plants producing colored concrete in a process that involves frequent changes of color.

Over the years, the Conflex system has been supplied to every part of the world and to all major organizations. Skako offers to evaluate any plant worldwide with regard to system use.