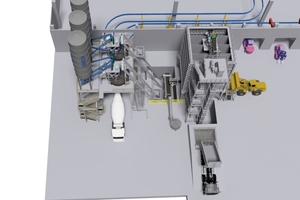

Wetbeton 100 horizontal precast concrete batching plant with distribution system for Ineton

Close to the Hungarian capital city of Budapest, Ineton is building one of Central Europe‘s most modern precast concrete plants, which will be put into operation in the near future. Apart from stationary production lines, the facility will also be equipped with two carousel systems for wall and floor elements as well as an automated machine for reinforcement steel processing.

The concept, planning and call for tenders for the plant was assumed by Prilhofer Consulting located in Freilassing (Germany) and Simem based in Verona (Italy) with a subsidiary in Lindau (Germany). The latter won the bidding process for the concrete production system and was awarded a contract for planning, manufacturing, supplying and installing the entire batching plant as well as the concrete distribution system.

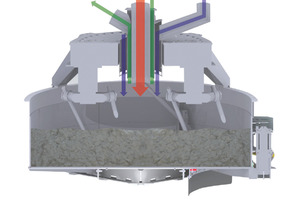

Planetary mixer

Two Xentrix 2.5m³ planetary mixers are used in this process; they are characterized by their off-center positioning of the main mixing arms and a patented central cement, water and admixture feeding system.

As water is added in a 360-degree umbrella pattern, a large part of dust is already captured during dosing. Moreover, the planetary rotation of the mixing stars generates a centrifugal effect, ensuring a particularly fast mixing of the mixture. The mixing plant is equipped with an automated washing system, mixer camera and sampling unit.

The horizontal batching plant provides space for 670 m³ of aggregates in eight different types, being fed through a discharge hopper with elevator and distribution conveyor.

Aggregates and concrete distribution

To be geared up for the constantly growing use of recycled materials too, the system is equipped with two special recycling compartments, featuring smooth interior walls, a steeper cone and discharge conveyors instead of gates. They can be charged by a wheel loader directly.

Two bucket elevators carry the material upwards to the two mixers, so as to ensure the best possible redundancy of the plant and to optimize the performance.

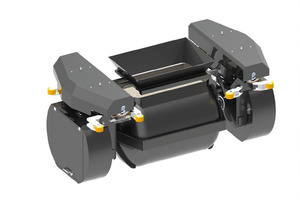

Concrete distribution is carried out by two Pelican bucket conveyors with a capacity of 4,500 liters each which are manufactured by a subsidiary of Simem (Simem SPIL). For mastering the complex course of the conveying system, the bucket conveyors have all-wheel drive and differential gears.

Automation and additional equipment

The concrete batching plant is provided with the Simem@tic control system (powered by Dorner), being especially developed for precast concrete plants, and has three release-order touch units which are installed in the production halls. The bucket conveyors are controlled via WiFi using a software that has been newly developed by Simem and is connected with the Simem@tic system. An automated concrete ordering process by the production machinery is planned for the future. The facility at the Alsónémedi location is designed so that the concrete production is constantly running in automatic operation without the need of any monitoring by the mixing plant operator.

In addition to the main plant and the concrete distribution system, the facility is also provided with a fresh concrete recycling system and a chamber filter press.

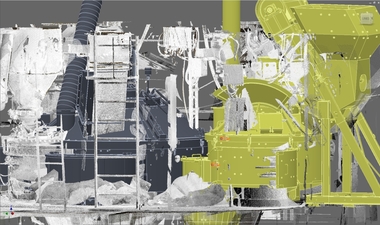

Planning and design

Right from the beginning, the plant was planned in 2D as well as 3D technology and in close cooperation with Prilhofer Consulting in order to meet the stringent specifications of the customer. In this regard, the long-term experience in the precast industry of Simem as well as Prilhofer was taken into account.

The customer Ineton attached great importance to the external appearance of the plant. All color shades were coordinated and had to be met exactly – and the result is very impressive.

Conclusion

Gönczöl Péter, director of Ineton, drew a very satisfied conclusion: „We decided in favor of Simem because the technical concept exactly fitted in with our plant. The price was fair and the new Simem subsidiary in Germany assures communication in German language.“