Connection of sandwich panels and concrete simplified

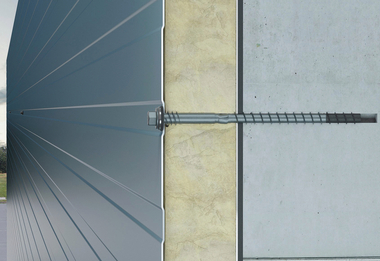

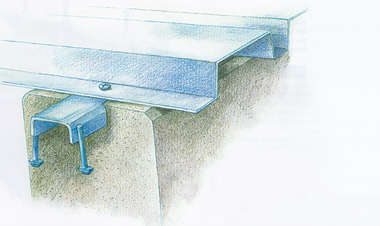

The Swiss SFS Group is a specialist in fastening solutions relating to the building envelop with more than 50 years of experience in this field. With the MXC fastener, SFS simplifies the installation of sandwich panels onto concrete. Because the thread rolling screw is a direct fastener, without the need to set steel channels in concrete. While the exact position of the channel plays an important role in conventional installation, the MXC fastener ensures a high degree of flexibility. The screw is an option even if the channel has been forgotten accidentally in the planning process or during production of the precast concrete element.

Simple planning and production

Planning of fastening by means of MXC made by SFS is simple, since the srew can be positioned flexibly in the later installation process. This minimizes possible sources of error as well as the complexity. As the steel channel is no longer required, there is no need for embedding it in concrete during the production of the precast concrete element - thus, another step is eliminated which might bear potential for inaccuracies.

The MXC fastener assures a positive connection free of expansion pressure - comparable to that of an undercut anchor. The direct fastener can be used quite close to the concrete edge as well. Screwing is carried out through a pre-drilled hole by push-through installation. The thread geometry provides for easy screwing in concrete and a high load capacity. Thus, the MXC fastener can be loaded immediately after installation. The actual screw is made of stainless steel A4 and has a toothed screw tip consisting of hardened carbon steel, which also minimizes the effort needed for screwing the fastener in.

Structure with a long-life cycle

According to the manufacturer, even atmospheric conditions cannot impair the sandwich-concrete structure: The screw is offered with a pre-assembled EPDM sealing washer as standard. The latter automatically centers itself under the fastener head and thus provides for permanent impermeability to rain. The comparably large flange diameter also has a positive effect on the load capacity of the sealing washer and improves the long-life cycle of the overall structure accordingly. In addition, the direct fastener has a high screw head deflection for absorbing the thermal expansion of sandwich panels.

The MXC fastener is assessed according to the European standard (ETA-20/0115). „The direct fastener is the first of its kind and turns out to be a real game changer. Because the fastener allows for a new way of planning and installation,“ explains Harald Schwendenmann, product manager metal lightweight construction at SFS. Hence, the sandwich-concrete fastener presents itself as reliable and efficient solution even in case of demanding projects.

CONTACT

SFS Intec GmbH

In den Schwarzwiesen 2

61440 Oberursel/Germany

+49 6171 7002-0

de.sfs.com