Data processing center: protected from interception and lightning strike

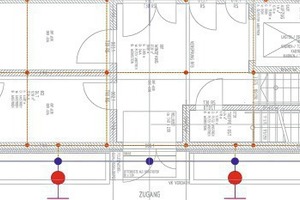

A very well protected building was to be constructed in the greater Koblenz area for a big company, serving the owner as data processing center. The building has a width of 21.35 m, a length of 28.1 m and a height of 16.25 m. The special feature of the structure is the shielding of the computer system by means of integrated shielding measures.

The construction of the building had to be carried out in compliance with all standards and regulations regarding shielding measures. Before casting the ground slab, the connections had to be inspected by the lightening protection engineer. Moreover, it was not only necessary to include all reinforcement of foundations, floors, etc. into the grounding measures, but also all metal façades and columns of the supporting structure.

Intermeshing up to the roof

For the realization of the project, conversations between all parties involved took place before the production was started in order to coordinate and define the responsibilities. A special quality control, among others, was stipulated regarding the implementation of the shielding measures in the production of the precast concrete wall panels. The plan of design specified columns as well as individual footings for the supporting structure. For economic reasons, the thermal wall was a perfect option, as it can be constrained into the ground slab because the reinforcement is already integrated at the factory. In addition to that, columns and individual footings are eliminated.

A successful realization of the project required to intermesh the reinforcement from the foundation up to the roof. The additional meshes merely served as electromagnetic shielding of the building, without any requirements in respect of lightning protection.

Faraday reinforcement cage

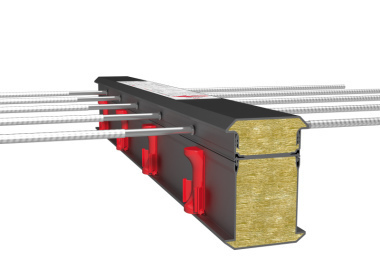

The precast concrete wall panels were designed with rebars as reinforcement layer. The longitudinal and transverse reinforcement applied at the factory was firmly tied together on the junctions with the aid of wire-tying machines; the horizontal and vertical junctions were welded so as to create a fine grid. Since the electric wiring was not intended for lightning protection but only for shielding purposes, machine tying was possible. The reinforcing bars were continuously inserted, without interruptions.

The terminal lugs used for the reinforcement of the precast concrete elements were welded to the grounding system of the foundation according to the axial dimensions of the precast concrete elements. In addition, every 3 m round wire as earthing mesh was inserted in the precast concrete elements, and the junctions of the round wire were welded. The terminal lugs enabled the connection of the reinforcing mesh to the protective bonding conductor in such a manner as to create a “Faraday cage”. This ensures that a disruption in the event of lightning strike will hardly ever happen.

1,420 m² of thermal wall were used for the concrete façade with a surface provided with hydrophobic treatment. The walls, having an overall thickness of 40 cm with 8 cm of mineral wool insulation, meet the fire protection requirements.

The thermal wall used was already provided with core insulation applied at the factory on the inner face of the external leaf. Compared to a triple-leaf masonry wall, the thermal wall provides better insulation values. Moreover, insulation and rendering works are completely eliminated on the construction site. Another advantage of the thermal wall is that assembly can be carried out indepen-dent of the weather.