Multifunctional insulation wall

The innovative Greencode insulation wall unit makes it possible to benefit from an industrial production environment as early as at the shell construction stage. Each wall unit is designed individually and produced under controlled conditions irrespective of prevailing weather conditions. These three-layer walls are delivered to the job site just in time. On-site installation is extremely quick, site logistics are simplified, and the need for time-consuming installation of formwork and reinforcement is eliminated. The entire range of building services has been incorporated in the Greencode workflow so that the wall units come either complete with all associated installations or are ready for integrating services, such as the floor slab used for heating/cooling purposes. This approach enables reliable planning of premium-quality construction projects even to tight deadlines whilst providing ample design freedom thanks to project-specific production.

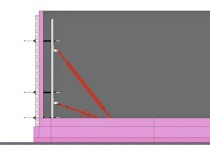

This insulation wall ensures a uniform indoor temperature because of the excellent storage characteristics of concrete. Depending on the season, incoming solar radiation stored during the day is emitted at night, or lower night-time temperatures are utilized for cooling on the next day. Building efficiency is further enhanced by the option of adding a heating/cooling element to the wall surfaces, which significantly enlarge the effective area and further reduce flow temperatures during operation of the heating system, thus making the use of renewable energy sources even more economical. “During cooling, outputs of up to 100 W/m² can be achieved,” says Hermann Rudolph, of Concrete Rudolph, Weiler-Simmerberg, Germany. Higher flow temperatures also reduce the amount of energy needed in summer and consistently protect the system against condensation without compromising performance, even during hot and humid weather.

Hard outer shell

Greencode insulation wall units are cast onto metal forms in horizontal position. Along with multi-stage compaction, this production process lends a smooth surface to the walls, which is the perfect recipe for visually appealing concrete. Concrete surfaces are cleaned and finished on the job site. Any conceivable design option is available to those wanting to benefit from the advantages of this insulation wall whilst wishing to conceal the concrete surface in some or all parts of the wall structure. All surfaces can be painted, both internally and externally. The inner and outer concrete shells feature integrated reinforcement and an intermediate insulation layer. Cast-in-place concrete fills the void in-between to make the wall unit a monolithic element.

In the Greencode design concept, the insulation wall forms the hard outer shell. Internal insulation ensures maximum fire protection. Various insulation materials are available, enabling thicknesses from 4 to 22 cm depending on the material and specifications.