Duct covers made from carbon-reinforced concrete

Carbon-reinforced concrete is suitable for a number of applications, including façades, walls, columns, beams, floor slabs, and modular buildings, as well as for repairing and upgrading existing structures. A precast production environment appears to be particularly beneficial for manufacturing carbon-reinforced concrete components; it is thus the predominantly used method at this stage. One of the reasons for this trend relates to the uniform, optimized conditions prevailing at the precast plant, which enable the production of more slender components at a lower cost than, for instance, with cast-in-place concrete. When comparing these two methods with each other, one of the key criteria is their cost effectiveness, besides resource efficiency, manufacturing conditions, and health and safety. For economic use of carbon concrete, instead of reinforced concrete, application areas for which exposure imposes high requirements are especially suited.

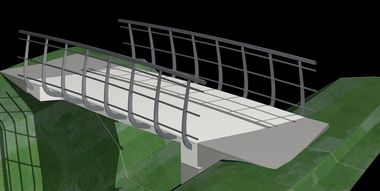

Pipelines laid inside ducts and culverts are often used for transporting district heat. Such pipelines are covered with precast reinforced-concrete elements, which come with the advantage of providing maintenance access to the pipes. Previously used duct covers are susceptible to corrosion owing to their permanent contact with the soil. This is why the main issue lies in the corrosion of the steel reinforcement, besides changes in the use above ground. In the event of a breakdown, network operators may be confronted with high costs incurred by the disruption and required rehabilitation of the infrastructure. For this reason, existing duct covers are replaced with new reinforced-concrete covers as part of a preventative maintenance scheme. However, these measures do not address the underlying issue because these exceedingly massive precast items continue to be susceptible to corrosion. A feasibility study was thus conducted in order to investigate if carbon-reinforced concrete was suitable for being used for the current duct cover design. The newly developed carbon-reinforced concrete duct cover led to a reduction in weight by about 50 % while providing the same structural capacity. Furthermore, a comparison of the cost effectiveness of these two methods proved the monetary benefits associated with the use of carbon-reinforced concrete.