Ecologically optimized timber-concrete composite

floors systems

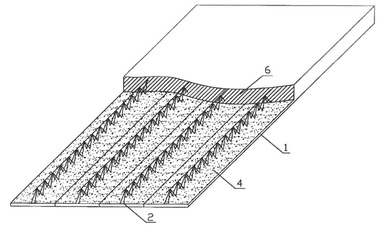

When it comes to performance and fast construction time, timber-concrete composite floors systems (TCC floors) are a feasible and resource-efficient alternative to conventional reinforced-concrete floor slabs. Moreover, substantial CO2 savings are possible owing to the fact that approximately the lower 2/3 of the reinforced concrete cross-section (tension zone) is replaced by wood. An ecological optimization of the concrete mix design and the use of non-metallic reinforcement provide additional potential for savings. The investigations

conducted at the University of Applied Sciences Augsburg are focusing on binders based on calcium sulphate and calcium sulphoaluminate as well as carbon- and basalt-fiber textile reinforcement which are tested in wood-concrete composite floor systems as part of the ForCYCLE II collaborative project.

The tests conducted so far on building components with notched connections show that TCC floors using more ecological concretes and textile reinforcement withstand at least the same load-bearing capacity as conventionally manufactured wood-concrete composite floors. However, the resource efficiency and CO2 footprint are improved significantly. Ongoing tests in practice should reveal whether shorter construction times will also be possible as a consequence of the setting behavior and the simple reinforcement installation. Long-term tests are still being carried out for ensuring the durability.

On the basis of all investigation results, recommendations will be worked out for dimensioning and execution, intended to facilitate a market launch.

Additional potential for development is seen in the use as precast floor slab and with regard to reconstruction and recyclability. R & D

activities will be strengthened in this respect at the University of Applied Sciences Augsburg in the future.