Fiber-reinforced concrete elements for tunnel in Israel

The Gilon Tunnel is situated on the 23 km long stretch of the railway line from Akko to Carmiel. The double-tube railway tunnel features a length of 4,700 m and a diameter of 8.5 m per tunnel tube. The tunnel was a still missing puzzle piece of the 145km long railway line between Tel Aviv and Carmiel. It is moreover one of the first two lines in Israel to be electrified. Owner and constructor is the Israel Railways Company.

Two years ago, the renowned planning company Bridge Design Services AG based in Zurich contacted Brugg Contect AG enquiring about the feasibility of slab track systems designed to carry vehicle traffic in rail tunnels if such slabs are manufactured with synthetic macro fibers instead of conventional reinforcing bars. These slab track systems are precast concrete elements which are primarily used for railway tunnels and are laid between the tracks. Such kind of slabs allow rescue vehicles to drive in and drive out of the tunnel without any problems.

Precisely fitting

Since Brugg Contec AG already participated in projects with the same task specification – the Schlüchterner Tunnel in Germany, for example – the company managed to convince the planning team for the tunnel in Israel with these references as well as a structural design. The Concrix ES bi-component macro fiber is excellently suited for such applications. The fiber is predestined for this purpose because of excellent performance parameters as well as the long-lasting creep tests.

The essential reason for the use of macro fibers in the Israeli project, however, was the geometry of the precast elements. The elements measuring 1.29 x 1.22 x 0.20 m are provided with recesses which precisely rest on the rails of the concrete sleepers. The production of such elements in the conventional way by means of reinforcing bars requires much effort and is cost-intensive and time-consuming. Casting the molds with synthetic fiber-reinforced concrete, on the contrary, is simple and provides the manufacturer, the company installing the elements, and the later owner of the tunnel with various advantages such as cost reductions, protection against spalling during transportation and installation due to three-dimensional reinforcement and long service life.

Exact fiber proportioning

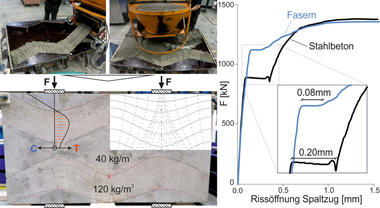

On the basis of the structural analysis of Brugg Contec AG, the team of Bridge Design Services AG carried out additional detailed tests and calculations. With the aid of the „Lusas“ software, it was possible to design the elements even more precise and eventually determine the proportion of the fiber at 3.0 kg/m³. According to the statement of the responsible engineer, these calculations enabled them to evaluate the actual ultimate load very well.

The Solel Boneh precast factory and Ackerstein Ind. Ltd. manufactured the overall 22,500 fiber-reinforced concrete elements on site in Israel. Prior to the production, tensile and load tests were carried out on the test facility by means of test specimens. The block elements were moved to the tunnel construction site in a simple manner by means of a truck/crane unit.