Repair and new construction using precast UHPFRC elements in the Deutsche Bahn railway network

Maintaining our infrastructure is one of the most important tasks and challenges of our time. When it comes to deciding between new construction or maintenance within the rail infrastructure of the Deutsche Bahn network, the focus is on rapid construction causing the least possible disruption to railway operations, the design of durable, low-maintenance structures, and cost effectiveness.

In this context, cement-bound ultra-high-performance fiber-reinforced composite (UHPFRC) is a viable alternative to conventional construction materials, particularly for strengthening or extending the service life of existing infrastructure. UHPFRC consists of a highly robust and durable cement matrix mixed with steel fibers. The high packing density of the fiber composite makes it impervious to liquids. UHPFRC cures quickly and can be installed in thin layers thanks to its high bearing capacity.

This paper discusses the repair of masonry vault bridges using UHPFRC as an example of its use in structural maintenance. Such bridges usually have a high residual structural capacity such that their service life can be extended significantly by targeted repair activities. The most common deficiency of a vault bridge is lacking maintenance, with no or only partial waterproofing. In many cases, the cover at the apex of the arch is also insufficient, which can only be compensated by weakening the arch geometry or increasing the track gradient.

One possible solution to this issue is to use UHPFRC since a layer of this material is capable of both sealing and strengthening the structure.

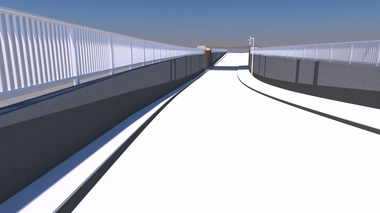

Yet there are also useful applications for UHPFRC in new construction. UHPFRC-steel composite components, for example, can be designed with extremely slender cross-sections. In new railway construction, designing rib-reinforced, 8 cm thick UHPFRC ballast troughs appears to be feasible.

In the long term, the use of innovative materials such as UHPFRC provides the opportunity to reduce resource consumption, increase construction capacity, and create a durable infrastructure.

This paper presents possible applications of UHPFRC in the maintenance and new construction of infrastructure projects, as well as the associated benefits. In addition, it outlines the approach to dealing with potential risks in relation to approval procedures (internal corporate and project-related approvals).