First fully prefabricated motorway bridge built in NRW, Germany

Following what could be termed a record-breaking short construction time of only 100 days, the new Hammacher Strasse bridge in Hagen in the German federal state of North Rhine-Westphalia, spanning motorway A 46, was put into operation at the end of July after a construction time of only 100 days. The new structure is the first replacement bridge in North-Rhine-Westphalia to be fully constructed as a precast concrete system – the girders are made of steel, and all the remaining parts, including abutment, roadway slabs and bridge caps, are precast elements.

The new bridge replaces an in-situ concrete bridge, which had spanned the A 46 in the same place. The original bridge, 50 years old, showed shortcomings in its loadbearing capacity and had to be dismantled.

Construction time as short as possible

The concept for the new bridge originates from Sweco GmbH, based in Bremen, Germany, and was the winning entry of an idea competition in 2016, sponsored by Strassen.NRW, the state road building agency for planning, building and operating all motorways, interstate highways and country roads in North Rhine-Westphalia. Participants in the ideas competition had been asked to submit new concepts for bridge construction in prestressed-concrete, steel or composite construction, to include new materials and technologies. The concepts were in particular to be characterized by the minimum possible construction time at the site, and construction activities were to interfere as little as possible with traffic.

The jury members included representatives from the German federal and state ministry of transport, the Bau NRW chamber of construction engineers, the Strassen.NRW agency of roads as well as from the city of Hagen. Prof. Dr.-Ing. Josef Hegger of RWTH Aachen contributed to the selection process as expert advisor.

Around 180 precast elements

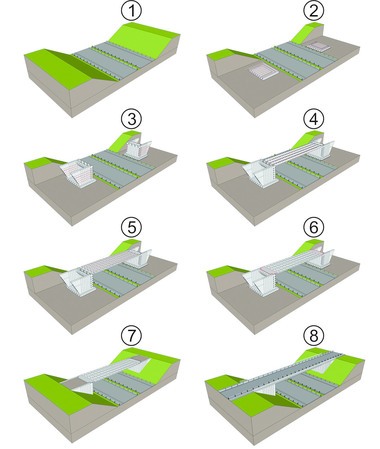

The precast elements for the replacement bridge were manufactured by Otto Quast at its Freudenberg precast plant in Germany, located just about 80 km, or 1 h by car, to the southeast of the construction site in Hagen. The workers in the plant manufactured a total of 68 large and 110 smaller precast elements. The largest precast elements, the longitudinal beams in the superstructure, are up to 40 m long and weigh around 30 tons, and the heaviest precast parts, the abutments and foundations, have a weight of up to 57 t.

The bridge was built by the Heitkamp Unternehmensgruppe headquartered in Herne, Germany. The bridge was constructed in about 100 days, as stated above, or 3.5 months. During this time, Autobahn 46 had to be totally closed to traffic on Saturday and Sunday nights – this had been necessary for the first time for demolition of the old bridge and for the second time for erection of the steel girders for the new bridge. For laying the bridge decks and the bridge caps, the motorway had to be fully closed to traffic four times at night, only on one side (i.e., in one direction of travel).

Precast parts as advantageous alternative

Strassen.NRW is responsible in North Rhine-Westphalia for supervising around 10,000 bridges. The majority of the bridges was built in the 1960s and 1970s. In 2016, according to the agency’s own information, more than 90 % of these were in good condition. However, around 800 bridges are in the focus of closer inspection. Their age – and primarily their greater loading, with increasingly heavy trucks – weigh heavily on the bridges.

In the medium term, many bridges will have to be replaced by newbuilds. For this purpose, precast elements can be recommended as an advantageous alternative to conventional in-situ structures.

Text: Christian Jahn, M. A.