Hammacherstrasse bridge over motorway BAB 46

in Hagen, Germany

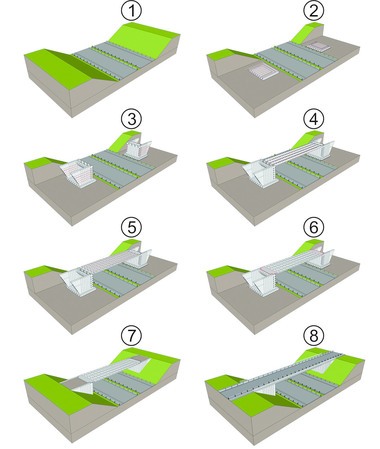

The first modular bridge in the German state of North-Rhine/-Westphalia (NRW) was erected in 2016 as the result of an idea competition of the NRW Ministry of Transport and the Chamber of Construction Engineers “Bau” conducted for speeding up bridge construction sites and for reducing traffic closure. SWECO GmbH had won this competition with an integral composite steel frame construction.

HEITKAMP Brückenbau GmbH was awarded the contract as general contractor, and OTTO QUAST Fertigbau Lindenberg GmbH & Co.KG was commissioned to manufacture the precast elements required for the project.

The bridge has an overall total length of 42.80 m, a width of 11.60 m and passes over motorway BAB 46 near Hagen. It is composed of approx. 180 precast elements with individual weights of up to 62 tons, which were required to be manufactured ând assembled to high precision specifications.

Construction took place from April to August 2018 over 100 calendar days, with the motorway partially closed to traffic on only three weekends. Traffic on the A46 was only minimally impeded: two lanes were at all times available in each direction of traffic.

The bridge foundations, embedded on vibrated stone columns with ballast, each consist of seven individual foundations for every bridge abutment side. These were glued together and tensioned. Due to the 28 GEWI connecting bars in the foundation, which were required to fit in their installed position into the abutments resting above, very special measures were required here to ensure dimensional accuracy.

The two abutments of the bridge consisted of four individual members on the north side and six on the south side. The very high reinforcement percentage of the highly complex embedded parts presented a special challenge. In order to ensure that the concrete fully encases the above embedded parts, the upper four abutments were required to be manufactured upside down and afterwards inverted by three cranes.

The 14 bridge decks were subject to very narrow tolerances and weighed 46 t each; they were provided with a large number of heavy embedded parts (up to five tons each).

Trials conducted on this construction method have shown that it can considerably reduce construction time at the site and should be used more widely in the future.