Flexible concrete frames for houses

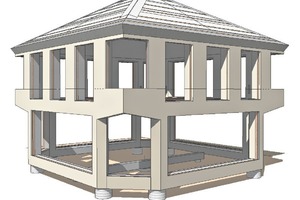

AB Finja Prefab, a Swedish producer of concrete elements, has been manufacturing precast elements for a particular type of house for over 20 years. Despite this long-standing market presence and its success in Sweden, this unique precast element design is not very popular in other countries. Not just the external walls but also the roof structure consist of 0.5 m thick sandwich elements made from concrete. The octagonal concrete frame is fully self-supporting, which enables unrestricted flexibility. Loads are distributed across eight corners. The house’s footprint amounts to only 88 m²; however, it includes a total living space of 147 m² with up to eight rooms and a kitchen. Furthermore, the design makes it possible to add eight different extensions.

This type of house, its concrete elements and the specially designed assembly system were developed by Swedish architect Ola Torrang SAR/MSA. Torrang previously worked in Japan and got inspired by the Japanese approach to flexibility, lighting and similar features. He combined the insights gained in this country with an advanced construction system and sophisticated energy efficiency specifications.

Easy installation of the building foundation

The foundation of the building is composed of eight concrete bases, each with a diameter of 600 mm. Each building corner features one of these bases, irrespective of the house being built with a foundation slab or crawl space underneath. If a foundation slab is cast, this happens only after assembly of the load-bearing concrete frame. No formwork is required for this purpose because the wall units fulfill this function. This work step is extremely easy because the eight bases are grouped around the center of the house; the only required tools are an angle tool and a 5.2 m long yardstick.

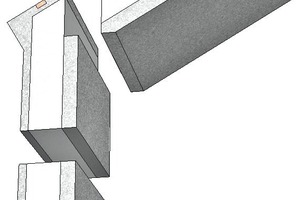

Complete with its roof, the entire building consists of only four different element types: two for the wall units and two for the roof, complemented by a fitting piece for the wall. The ground floor has an octagonal layout whereas the upper floor is rectangular. Due to the ground-floor element height of 3.6 m, the joint between the two elements is located at the upper level, 40 cm above the floor, which is why pipe and cable conduits can be linked to the corresponding ground-floor installations without having to insert any additional joints.

Quick and easy assembly

The concrete frame is usually erected within two days, requiring three skilled workers and a 50 tonne truck-mounted crane. The assembly process can start with any side of the frame. In the first step, the four ground-floor wall units with embedded hardware are bolted together at the corners. Two steel beams are then placed on their base plates integrated in the wall units.

The roof elements are assembled using two 7 m long, specially designed steel supports whose lower end includes a remote-controlled hydraulic lifting device. The crane lifts the first roof element into place; it is then supported and moved into the specified slope using the lifting device. The opposite roof element is mounted in the same way. The two roof elements located in-between can then be mounted without supports. The roof elements are bolted together from below and form a self-supporting structure. The remaining roof elements are mounted using the same method.

Unrivaled flexibility

The design of the concrete frame aimed to provide a high degree of flexibility, maintenance-free operation, and an efficient construction method. It is always problematic to insert larger openings in a concrete structure after the construction phase, which is why the wall units were designed with 24 openings, enabling a perfect choice of the location of doors and windows. Any unused openings are “filled” with blind windows or curtain walls. If any alterations are planned at a later stage, blind windows can be replaced with real windows.

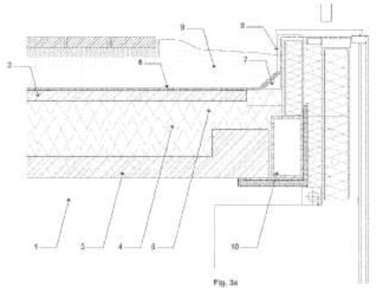

The lower part of the roof forms a cornice. The fact that the cornice is part of the wall unit is associated with two advantages: first, there is no cold bridge; second, there is no visible joint between the roof and the wall unit. The upper floor rests on two steel beams that are placed on sturdy support plates mounted on the wall units, which completely prevents any cold bridge that would otherwise be created.

The sandwich wall units are insulated with a 300 mm layer of expanded polystyrene. The client can freely use the 24 wall openings to insert doors, windows or infill walls. Depending on the client’s requirements, the thickness of the insulation can be increased to a maximum of 45 cm.

The concrete volume amounts to 20 m³ and stores excess room heat, which results in a comfortable, uniform indoor climate because warm air moves in upward direction, towards the roof elements that comprise the major share of the concrete volume.

Perfectly suited for groups of “custom” buildings

Thanks to its unrivaled flexibility, this house design is perfectly suited to constructing groups of custom buildings, particularly in terms of its cost effectiveness because it always uses the same frame and thus enables an efficient construction process. Their compact footprint (9.4 x 9.4 m) makes these houses also suitable for relatively small plots of land (450 m²).

Interested companies may approach Ola Torrang Arkitekt SAR/MSA, who will offer them an arrangement to manufacture and distribute these houses under license.