Brüninghoff manufacturers wall and floor elements for new office building on „Wissenscampus“ in Stuttgart

The Wöhr + Bauer real estate company has high demands in respect of ecological building as far as the construction of the new W15 office building in Stuttgart is concerned. Thus, the consumption of resources is to be reduced and emissions are to be minimized. In order to meet these requirements, the project parties opt for a wood-concrete hybrid construction method with a high degree of prefabrication. This not only leads to more sustainability, but also to fast progress in construction. Wall elements and wood-concrete composite floor slabs (WCC floor slabs) of Brüninghoff are used here. The latter, above all, offer technical, economic, and ecological advantages. Because the elements combine the positive characteristics of wood and concrete and make use of the synergy effects of both materials.

Being the second largest industry location within the city boundary, „Wissenscampus“ in Stuttgart accommodates numerous business enterprises. Now, the site is supplemented with an attractive new building – the W15 – made in wood-concrete hybrid construction, pursuing the existing building structure expertly. The five-story building offers a floor space of about 6,100 square meters. Based on the construction plans of the local architectural office, wma architekten wöhr mieslinger assoziierte, the building is realized at present by Brüninghoff in a joint venture with Rommel SF-Bau GmbH & Co. KG.

System concept according to CREE Buildings

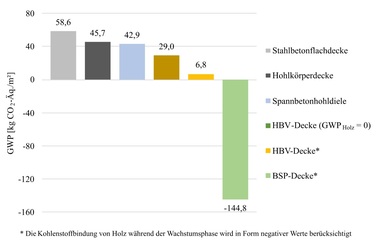

For the W15 building in Stuttgart, Brüninghoff manufacturers and installs the hybrid load-bearing structure – this includes composite columns, wood-frame walls as well as wood-concrete composite floor slabs, among others, in accordance with the CREE Building approach. The floor slabs consist of a grid made of prefabricated wood-concrete ribbed floor slabs in the dimensions of about 2.7 meters x 8.10 meters and 6.7 meters, respectively. They are composed of wood beams in composite with a reinforced concrete slab. Thanks to this combination, the hybrid building component scores both in terms of technical and economic advantages: It is significantly lighter than conventional concrete floor slabs. In comparison to usual concrete floor slabs with a thickness of 30 centimeters, using wood in Stuttgart saves around 50 percent of concrete. In the utilization phase, contrary to inorganic building materials, wood moreover stores carbon, being captured by the conversion of carbon dioxide in the wood during the growth of the trees. Hence, the substitution of mineral building materials and the sequestration of carbon make a positive contribution to climate protection. In comparison to a pure wooden floor slab, the hybrid component achieves a higher stiffness and load-bearing capacity. The used element is designed in a fire-resistant F90 quality.

Combination of primary and secondary construction steps

The slabs consist of a 10cm-thick concrete layer and ribs with a cross-section of 24 x 32 cm. The notched connection by means of bolts structurally provides a very strong bond. The edge zones towards the façade are designed with continuous concrete edge beams. They are resting on double columns made of glulam, transferring the vertical forces via the floor to the pair of columns beneath. Brüninghoff prefabricated these columns including the exterior wall elements and windows. The basic elements on the first floor have dimensions of around 8.09 meters x 4.08 meters; on the standard floors the width amounts to approx. 8.09 meters and the height to 3.58 meters. An element consists of several pairs of columns, being installed as one façade element on the construction site simultaneously. As a result, both primary and secondary construction is mounted in one step. This not only ensures optimized construction progress, but also closes the building envelop in a short time – this increases the quality of execution as a weather protection is provided faster.

Inside the building, the wood of the ribs and columns remains visible in its natural shade, thus contributing to the attractive space offer of „Wissenscampus“. The sustainable concept includes, moreover, an intensively greened roof as well as a photovoltaic system along with hot water heat pumps. These factors contribute to the fact that the KfW 40 house EE standard is obtained. In addition, the certification according to LEED is aspired.

The W15 office building in Stuttgart demonstrates in an impressive way how the system concept of a hybrid construction method can be incorporated lucratively into a building. Because the concept not only scores in an ecological aspect, but also is a quality factor.

CONTACT

Brüninghoff GmbH & Co. KG

Industriestr. 14

46359 Heiden/Germany

+49 2867 9739-0