Global innovation in bridge construction

With the type of „folding bridge“ developed at TU Wien another Austrian innovation does exist that saves costs and time in the implementation of infrastructure projects. Two bridges are being erected on the S7 expressway, crossing the Lahnbach and the Lafnitz river. A total of 22 bridge structures will be built there; the two folding bridges are the largest ones. The environmentally-friendly construction method used for the bridges works like an umbrella. „It is a new construction method where we manufacture the bridge in vertical position. We can save a lot of money in comparison to other methods,“ explains Prof. Johann Kollegger of the Institute of Structural Engineering/Concrete Construction at Vienna University of Technology (TU Wien).

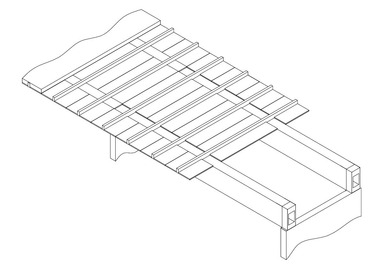

Vertical bridge girders are mounted on both sides of a concrete pier, and then they can be unfolded. The two girders are connected to each other at the top, directly above the pier, using a joint. Then, hydraulic systems slowly lower this joint and the girders unfold to both sides. Once the girders have been reached their final position, they are filled with concrete; this method does not require any scaffolding.

Folding bridges environmentally friendly, space saving

In this way, construction time is shortened and above all a large impact on the natural landscape is avoided. „Especially in the region of Lafnitz and Lahnbach, it was important to us to proceed as carefully as possible,“ states Bernhard Streit, manager at Asfinag. The adjacent wetlands and „Natura 2000“ prompted Asfinag to search for an alternative bridge construction method. Initially, they planned to use reinforced concrete superstructures. Besides protecting the environment, the new technique of unfolding a bridge provides considerable economic benefits. The manipulation areas used for the construction of the center pier are not enlarged compared to the design of the steel-concrete composite bridge.

Lowering of the folding bridge takes place in a slow process and takes three to four hours on average. A bridge girder is 36 m long and weighs 54 tons. „The folding bridges were erected because of their environmentally-friendly construction method and moreover they are very space saving,“ Streit says. The section of the expressway is to be completed by August 2021. The last of eight unfolding procedures in total took place on July 01. The lowering process of the concrete girders weighing more than 180 tons used for the Lafnitz bridge with an overall length of 117 m was successful like the previous ones. The two girders had been unfolded after roughly four hours.

The concrete elements for this project – a total of 660 m³ of precast girders and compression struts – were supplied by Franz Oberndorfer GmbH & Co. KG.

Traffic congestion relief as an objective

The S7 (Fürstenfeld expressway) is being constructed in the south-east of Austria in the states of Styria and Burgenland in order to cope even better with the high traffic volume from and to Hungary which is resulting in congestions and traffic disturbances on the federal road. After the completion of the S7, the road safety in the region will be improved by relieving the thoroughfares. In addition to the 22 bridge structures, an underground passageway, two tubs, a mined tunnel, two deer crossings, and six passages are required for the Fürstenfeld expressway comprising a 15km-long west section and a 14km-long east section.

„According to the design concept of the prestressed concrete bridges using the new technique of unfolding a bridge, the bridge sections with a length of 72 m are folded starting from the center pier. Afterward, mobile cranes situated behind the abutments can lift the precast concrete girders into position, which are connected to the end of the folded bridge sections and are lowered to rest on the abutment. After the installation of the bridge section, the carriageway slab is constructed by means of a composite formwork carriage as used for steel-concrete composite bridges,“ explains Clemens Proksch-Weilguni, assistant to Prof. Kollegger.

Using thin-walled, prestressed precast concrete elements subsequently complemented with cast-in-situ concrete has the advantage that the forces acting during the lowering process are lower than that acting in case of erecting the folding bridge in the already finished component dimensions. Lower forces acting during the lowering process allow for a more cost-effective dimensioning of the joints, which have to take up the reciprocal torsions of compression struts and bridge girders during folding. „The technique of unfolding a bridge is particularly advantageous for bridges with high piers because in such case there is no need for the erection of an auxiliary pier. The compression struts reduce the span, allowing for considerable cost savings,“ Prof. Kollegger states.