Handling of interlocking concrete block cubes: feeding, destacking, stacking, turning

Although the production of interlocking paving blocks is largely automated, there are still process steps in which the not yet strapped and therefore unstable block layers must be shifted. For these interfaces, Probst offers its intelligent and extensively proven solutions.

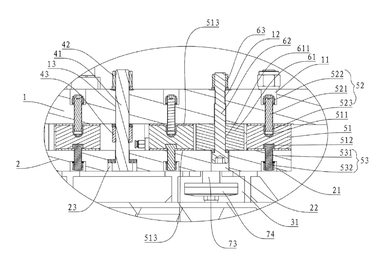

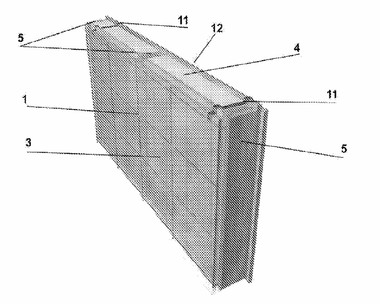

The ATZ-P pneumatic cubing plant enables destacking or stacking of up to two interlocking block layers. The transport clamp is attached directly to the hook of a craneway and is controlled with an ergonomic guiding handle with an integrated manual control valve. A pneumatic locking cylinder holds the blocks on two or on four sides in a secure grip. For integrating this cubing plant into an automatic stacking plant, purely electric drives are available as an alternative to pneumatic drive. A vertical guide, the SFR-900 system with built-in chain guide, stabilizes the unit during traveling.

For turning concrete products such as steps, edge angles, and curbstones by up to 180o, Probst has developed the P-WEG pneumatic clamp. Clamping and turning the bulky products around the longitudinal axis here take places pneumatically and thus for the operator virtually without physical effort. This enables the blocks to be transported, for example, ready for wall construction to the building site – thus reducing installation time. Both an electric and a hydraulic variety are available with each of these functions.

Turning and shifting with the stacker

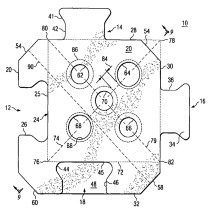

After production, interlocking blocks and concrete elements must first be placed in interim storage in the manufacturer’s yard and subsequently picked. The STAZ forklift grabs from Probst, owing to their modular system, offer maximum flexibility for these operations. They are designed for rugged use on the stacker and securely hold even unstrapped, multi-layer interlocking block cubes. The high-strength steel of which they are made provide them with very high loadbearing capacities of 2,400 to 4,000 kg at low self-weight. Easy exchange of grippers enables variable gripping of all standard construction material packages of widths from 370 to 1,370 mm.

Firmly screwed-on grips with and without rotary motors, double grabs, and double grippers support a variety of requirements. Six varieties of the STAZ forklift grabs offer clever solutions for all relevant handling tasks for whatever demands are encountered: rapid pickup of tools, high hoisting, stability, and rotary movements. In addition, one variety offers the option for using the traveling time not only for transporting material, but also for simultaneously compacting the cubes. This saves both valuable storage space and time: compaction and grabbing in one work step.

The grabs, depending on the requirements, can moreover be fitted with rubber or steel lamellas, or with double-steel lamellas. And Probst also has the best solution for very special layers of material: for example, interlocking block cubes that are not compacted and not strapped, or also for thin layers of concrete block and sensitive sand-lime brick cubes.