Harmonious connection

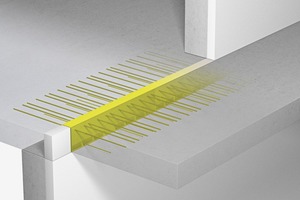

A lot of acting forces have to be balanced in terms of statics when it comes to realizing balconies, one’s own realm under the open sky. Moreover, high legal requirements concerning airtight façades with thermal insulation must be fulfilled. For many years now, H-Bau Technik GmbH has been offering well-proven solutions for such thermal challenges with their Isopro elements. They connect concrete structures to the façade in a statically reliable way, thus avoiding thermal bridges simultaneously. The integrated tension and shear bars as well as the pressure pads absorb bending moments and shearing forces reliably.

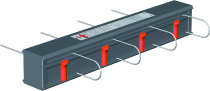

Now, the load capacity of the pressure pads has been increased for the Isopro elements for connecting external and internal concrete components. The supplier to the construction industry, located in Klettgau in the south Baden region of Germany, was also able to reduce the diameter of the tension bars in the insulation joint by about 36 % by using a high-strength stainless steel. The improvements reduce the heat transmission while the static load capacity remains unchanged.

Owing to the high thermal conductivity of concrete and the large surface of connected external components in comparison to the connection cross-section, not or inadequately insulated connections lead to an enormous thermal flow. This results in high energy demand as well as condensation on cold inside surfaces, and thus mold growth. These weak spots are reliably eliminated by the use of Isopro thermal insulating elements of H-Bau Technik. Transferring static loads reliably at the same time, the elements by far surpass the minimum requirements of thermal protection according to EnEV and DIN 4108-2 supplementary sheet 2.

Further development

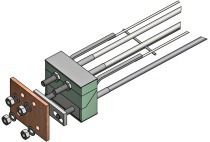

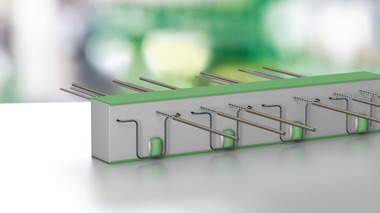

The pressure pad capacity of the concrete to concrete connection elements has now been significantly increased. The Isopro element provided with concrete pressure pads achieve considerably higher loading steps, resulting in many advantages. The steel pressure pads have been eliminated at some elements; they are replaced by the compact version made of special concrete. This version is lighter, does not protrude from the insulating body, thus being easy to install and showing a low heat transmission. In addition to this, the number of concrete pressure pads can be reduced due to the higher performance. In this way, the insulating effect of Isopro elements is additionally increased. Furthermore, the diameters of the tension bars were reduced within the insulation joint. Generally, the diameter of the stainless steel used there is now smaller than the reinforcing steel bars welded on. Using the high-strength stainless steel 1.4482 provides for the same load capacity, while the heat loss is again considerably decreased owing to the minimized cross-section.

The tension bars are fixed by means of the new fastening system “Easy Fix”. This system not only secures the reinforcing bars in their axial position, but also guarantees that the concrete cover is reliably met. The stability of the insulating body is moreover enhanced. In particular, positioning and fixing of two-part elements at the precast factory is done with effortless ease. The general technical approval No. Z-15-7-244 granted by DIBt has already been amended for the further developed Isopro connection elements. The further development of the product, moreover, eliminates the hanger reinforcement required so far, entailing additional advantages in respect of ease of installation.