Heliostats made from UHPC –

Modular ultra-lightweight construction

Heliostats are collectors designed for point-focusing concentrated solar power plants. A large number of heliostats concentrate the incoming solar radiation onto a receiver located at the top of the central solar tower. Conventional steel collectors should now be substituted by circular concrete structures. UHPC has already proved to be a promising alternative for line-focusing parabolic trough systems [1]. Since the precision requirements are more demanding for heliostats than for parabolic troughs, the extensive shells are transformed into strut structures, resulting in additional stiffness thanks to the associated increase in their effective structural height.

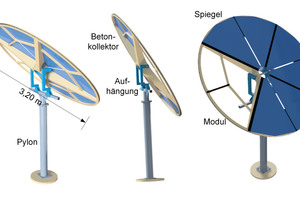

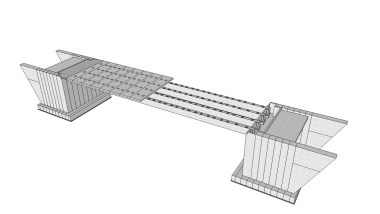

Symmetry reduction techniques appear to be appropriate for heliostat form-finding due to their round shape [2, 3]. For this purpose, the heliostat is simplified and idealized as a slab with central support, and divided into segments of equal dimensions. An equivalent stiffness approach is chosen to transform these segments into radial struts. Their dimensioning is limited by the maximum deformation parameters of existing systems [4] and the tensile strength of the UHPC. This approach prevents major deformation and ensures an uncracked condition of the segment according to the structural analysis. The modules are complemented by additional struts, including an inner ring connecting to the support, an outer ring allowing for external circumferential prestressing, and secondary struts ensuring the transfer of forces and providing additional support to the mirrors. The external circumferential prestressing results in compressive loads acting on the struts, thus holding the modules together. Serial prefabrication appears to be an appropriate method because of the modular design and the large number of heliostats in the solar collector field.

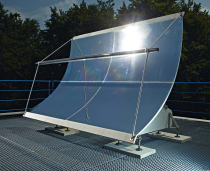

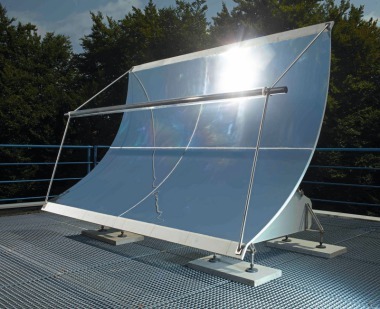

The feasibility of this design will be verified by a small-scale collector prototype that is currently being installed and subjected to optical qualification on the solar field of the German Aerospace Center in Jülich. This prototype comprises four 90° “pie segments” and has a diameter of 3.20 m, which is equivalent to a mirror surface of 8 m².