Integral building a key factor for the competitive edge

Integral building is a key factor for cost-efficient execution of a project. The company BT innovation has set the target of developing appropriate solutions and has been researching integral technologies since the turn of the millennium. This will open up critical competitive advantages for precasters. A comprehensive approach is needed for carrying out increasingly complex construction tasks. Inclusion of all consultants and trades at as early a point of time as possible enables a holistic approach. Here, the focus is not on partial aspects, but on the interaction of as many factors and their integral concepts as possible. In this way, precast plants will be included in the entire value-added chain from the very beginning and will therefore enable them to play a significant role in the planning process.

Precast elements must be sealed and connected at the construction site. Precast plants can ensure competitive advantages over local solutions by inviting involved trades to think along from the start. Towards this end, the company BT innovations has made significant developments. Development of the BT turnbuckle for dry connection of precast elements is regarded as the first of its kind and is today speeding up construction processes on many sites, e.g., in construction of a 15-story hotel building at London Heathrow Airport in 2018. Starting out as an in-situ concrete construction site, the developer changed to dry connected precast elements from the fourth floor upwards and was able to reduce the planned construction time by several months.

Combined use

Combined use of the BT turnbuckle and sealing tape of butyl rubber, e.g., RubberElast, enables instant sealing of the dry precast connections for up to a 5-m head of water – even during winter construction. Polymer-modified bitumen strips such as SynkoElast, and virtually shrinkage-free joint sealers, such as InnoElast, enable a combination of in-situ-cast concrete with precast elements and erection of precast elements largely independent of the weather. Integration of façade insulation in precast reinforced-concrete elements in the precast plant meet the increasingly more stringent requirements placed on better insulation of buildings, generally more reliably than local solutions. Here, composite anchors of glassfiber-reinforced plastic, such as ThermoPin, for connecting concrete shells by insulation, are setting new standards. It is important that the glassfiber bars are optimized for rapid processing. Composite anchors must, moreover, be able to absorb movements in all directions, nearly completely reducing susceptibility to cracking in the facing shells of sandwich walls.

The value-added chain can be integrally optimized in precast plants as well. Already years ago, magnetic technology found its way into production. But real effectiveness results only by supplementing the magnets with a precisely adapted formwork system. The initial time saving results from simply suspending the magnets in the formwork without requiring bolting. The unique foot-spring system of the MagFlyAP magnet simplifies moving the formwork and fast shuttering. The adhesive strength of the magnet, which can be activated after positioning, draws the formwork onto the steel table and securely seals the joint by applying pressure. With an adhesive force of 22,000 N and a weight of only 5.5 kg, the MagFlyAP magnet from von BT innovation, together with adapted MultiForm formwork, is a convincing high-performance system. Today, thousands of precasters are banking on the combination of high-performance magnets and adapted formwork systems for erecting formwork within minutes.

Integrated added value

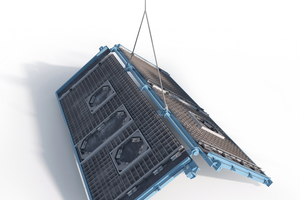

Production of precast elements smooth-formed on five sides directly integrates the added value of local rendering in the plant. Wall elements manufactured in upright position with smooth-formed surfaces ready-to-paint on all sides not only saves costs of on-site rendering, but also minimizes building moisture and reduces construction time. Utilization of battery formwork for vertical production has again been increasing in recent years. Two years ago, BT innovation, based in Magdeburg, Germany, introduced butterfly formwork. At that time, the development, patented worldwide, solved central problems that had even adversely affected battery formwork of state-of-the-art construction. One of the reasons for this is dependence on the frequency of occupation of the battery formwork on the strength of the precast elements when lifted out of the formwork. A further reason is the comparatively great amount of manual work required for setting up the formwork, placement of reinforcement, and making of electrical installations on the vertical form surfaces required for a standard pocket formwork.

Butterfly formwork, since launched on the market, combines the advantages of vertical and horizontal preparation, making it faster, more efficient and more flexible. Butterfly formwork can also be constructed for use similar to a circulating pallet. In this way, the battery formwork becomes part of a circulation system. Output in the order of magnitude of 500 or more dwelling units per month become possible: a capacity that on time-critical infrastructure construction sites can win out over local execution in favor of precast plants.