User-driven research for the future of precast production – butterfly formwork offers new opportunities

We are currently witnessing a remarkable development in the construction industry as the global trend towards prefabrication is gaining momentum at an impressive rate. BT innovation rises to the challenge of developing efficient production methods. The company developed a pioneering approach thanks to many years of expertise in developing and producing manufacturing systems.

BT innovation developed a groundbreaking approach: The company’s battery and butterfly formwork system combines the advantages of horizontal preparation with the option of vertical concrete pouring. Not only does this innovative solution permit precise preparation of embedded parts and reinforcement; it also integrates seamlessly into the process of vertical production of multiple precast elements. Modularization of the construction process results in considerable time and cost savings while also ensuring outstanding quality, which is achieved through efficient production in a controlled environment. This trend is gaining importance at record speed worldwide, most notably in the much-needed residential construction sector.

The butterfly formwork technology

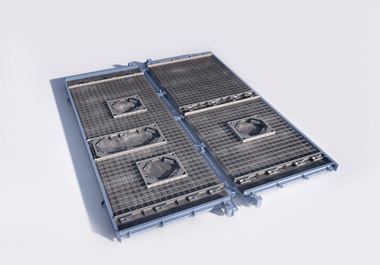

Modularization of components can take place in different stages, from individual beams and columns to wall panels and floor slabs, to complete modular units. Various methods can be applied for prefabricating large panels. Correspondingly, a wide range of equipment and machinery is available, each associated with its own benefits and drawbacks. Based on many years of experience in the design of horizontal and vertical production systems, B.T. innovation GmbH was in a good position for developing a battery and butterfly formwork solution that combines the advantages of horizontal preparation with the benefits of vertical concreting of precast elements. The butterfly system allows for simple yet accurate preparation of embedded parts such as anchors, door and window openings, utility lines and conduits, and reinforcement on a horizontal workstation. In the next step, the element moves into the battery formwork and functions as an integral component to enable the vertical production of multiple precast elements.

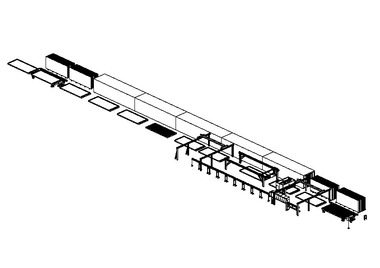

Combining horizontal preparation with vertical concrete pouring and storage makes it possible to integrate the butterfly formwork into existing carousel production lines, offering new options for increasing the efficiency and degree of automation in precast production.

Advancement and applications of the technology

Since its market launch, the butterfly formwork system has combined the advantages of horizontal preparation with vertical production. This has accelerated battery mold operation while also making it more cost-efficient and more flexible. At the current development stage, the patented butterfly mold can also be integrated into carousel production lines, which means that the battery formwork itself replicates this type of production line.

The carousel technology has increased the effectiveness of precast element production for many years, including solid walls, sandwich panels, balcony slabs, and custom components, while shortening production cycles thanks to optimized equipment and machinery and customized workflows. Integrating the patented butterfly system into a carousel line makes the battery mold compatible with such production lines, allowing for a high degree of automation and an exceedingly efficient overall process for battery molds. This approach also offers new options for optimizing costs for sandwich walls or prefabricated brick elements with a smooth inner surface. Integrating the battery formwork system into a carousel plant design combines the process benefits of the carousel technology with achieving the specified five-sided smooth surface while fully utilizing the high output potential of the battery mold.

Magdeburg-based company BT innovation originally launched the butterfly formwork system in 2015. This design was patented worldwide and resolved the two major issues that even the most modern, high-performance battery systems were associated with at the time: First, the frequency with which the battery could be occupied depended on the lifting strength of the precast elements. Second, a relatively high manual effort was required for formwork construction and reinforcing works on the vertical formwork surfaces in a pocket battery system.

The butterfly technology provided the solution to the first problem because precast components can be lifted together with the butterfly element only a few hours after concrete pouring and stored outside the battery for curing. Since the precast elements do not have to carry their own weight during lifting, the required waiting time is reduced. With a concrete strength of only 5-8 N/mm², precast units can be removed from the battery together with the butterfly. This would theoretically allow for up to four concreting passes within 24 hours, which, depending on the battery size, can translate to several thousand square meters of concrete produced additionally per shift.

The second disadvantage of conventional battery formwork systems is, according to the supplier, the high cost of formwork construction and insertion of reinforcement on the vertical formwork surfaces within the confined battery space. This design drawback was eliminated by developing the butterfly element, which can be removed separately from the battery and positioned horizontally outside it. This allows all work steps prior to concrete pouring to be performed in the horizontal position as effectively as on tilting tables or carousel lines, including laser projection for the exact positioning of formwork, block-outs, reinforcement, embedded parts, conduits, and magnets. Laser projection of precast production data at the touch of a button eliminates errors, reduces setup time, and streamlines the production process.

The butterfly principle was the key novelty when the system was launched. This design features a hinge that connects the two sides of the form to provide maximum flexibility. After completion of the preliminary work steps in the horizontal position, the butterfly is lifted into the battery formwork unit using a crane and an automated gripper beam, which minimizes slinging times and allows for quick transport to the battery. These lifting and transport operations can be performed by just one worker on the shopfloor. The real innovation is the butterfly’s folding feature ensured by the hinged connection of its two halves, which brings about the benefits of combining vertical storage and concreting in the battery formwork with horizontal preparation on the formwork surfaces.

Butterfly technology used in precast plants across the world

Several market leaders are currently using the butterfly technology: Three systems are in operation in Germany, one is used in Austria, and another butterfly battery was sold to a South American business. Since the end of 2017, patent rights have been held by Austrian Umdasch Group, which focuses on the construction and operation of mobile field factories. Licenses for stationary precast plants remain with BT innovation.

Setting the standard for high-quality, custom precast components

This technology enables precast plants to also produce components larger than 8.0 by 4.0 m. In the future, the formwork segments that can be removed from the battery will also be capable of being conveyed between the individual workstations outside the battery, similar to pallets on a carousel system.

B.T. innovation recently completed the detailed design and engineering phase for the first extension of an element-optimized butterfly carousel line for producing custom solid wall and sandwich panels with a five-sided smooth surface. On this system, precast elements with a high proportion of embedded parts and installations, high-quality sandwich walls, and architectural concrete façade panels will be produced. In a second extension phase, it will be possible to move workstations out of the actual transport sequence and move them back into the production workflow after widely different processing times.

Currently, the battery and butterfly formwork system is in use in Europe and Africa with various degrees of automation and complexity. Finished products are high-quality elements with smooth surfaces on five sides, which are either installed directly in buildings on-site or used in the factory as components for prefabricated modular units.

Paving the way with pioneering solutions for over 30 years

BT innovation stands for pioneering product developments in the construction and precast concrete industries. The company’s comprehensive portfolio, which includes sealants and waterproofing, shuttering magnets and systems, connector systems, and consulting, is complemented by the high-quality machines and production lines supplied by its subsidiary MAX-truder GmbH. For more than 30 years, its patented solutions have enabled B.T. innovation to make a major contribution to the successful completion of construction projects worldwide.

CONTACT

B.T. innovation GmbH

Sudenburger Wuhne 60

39116 Magdeburg/Germany

+49 391 7352 0