Innovation: Gertec SBM-8

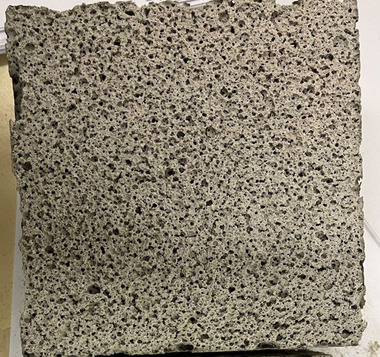

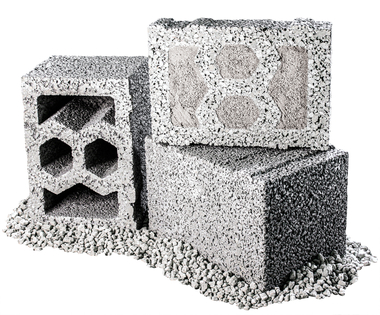

An air-hardening mineral foam made with mineral binders has outstanding advantages as insulating material. Gertec has developed a new, innovative mixing method for foamed concretes and mineral foams and the appropriate mixing plant for processing them.

For manufacture of a foamed concrete, a slurry is prepared from water and binders in batches in a colloidal mixer. The slurry is placed in a buffer container for intermediate storage. From here, it is continuously fed to the foamed concrete mixer and mixed with the continuously produced foam to an absolute homogenous and highly stable foamed...