Innovation: HTU-S – self-anchoring profiled metal sheet

The HTU channels of Halfen have always been an ideal system for fastening of profiled metal sheets of all kinds. The market potential of fixing systems for attaching metal profiles to concrete structures is estimated to approximately 6 million meters in Europe and will increase by about 3 % annually until 2025, according to current studies.

Solutions previously approved for fastening of profiled metal sheets used anchors welded to the channel lips to transfer loads into the concrete. Therefore, the reinforcement is often hit when the channel is inserted and the installation is much more difficult. The projects require a high planning intensity and different product versions which also increase the complexity in terms of procurement and storage at the precast plant.

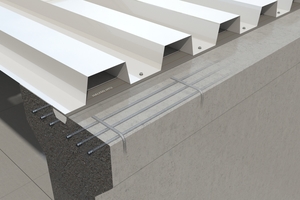

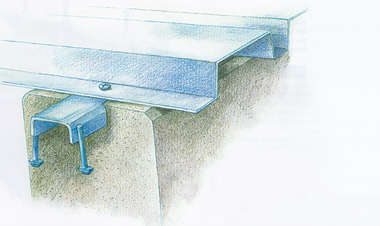

The two-year development process resulted in a solution that uses the lateral profiling to replace the conventional welded anchors. This profiled structure interlocks the channel with the concrete, acting there like a large number of very small anchors, which avoid that the channel is pulled out of the concrete. The double-bent channel lips in an interaction with the angled geometry of the filling material provide for forming a compression strut and the activation of the concrete. The related failure patterns are similar to those occurring with positive connections in practical application. Thus, tests with a screw spacing of only 150 mm could verify loads on a dimensioning level of 3.6 kN. In general, the dimensioning of the screws remains the decisive factor.

Covered with concrete

Thanks to the installation height of only 25 mm, the new self-anchoring HTU channel of Halfen is cast completely into the concrete cover. Therefore, it can be installed into the structural component totally independent of the reinforcement position. Due to the self-anchoring design, the channel can be cut to almost any length and thus adapted to the individual requests of the customers. In addition, the new channel helps save storage capacities and also indirect costs for the procurement of products, by minimizing the variety of versions.

Owing to the new, engraved product marking on the back of the channel, the HTU channel meets the constantly growing requirements on the obligation to provide proof in the construction projects. In this way, the product can be identified definitely and quickly when delivering the concrete elements to the construction site. Halfen has successfully filed patent applications for many details of the channel and the national technical approval (abZ) has also been applied.