Innovation: Siporit

The quality of the outer concrete surface is crucial for the durability of concrete components, especially when reinforcement is applied. Environmental influences may cause severe damage due to carbonation. Schools and other new public buildings are often embellished with exposed concrete elements. The focus on individualization throughout design aspects is increasing. However, those concrete elements are particularly vulnerable to damage caused by vandalism and abrasion. Unfortunately, the removal of soiling on concrete can be an arduous and expensive procedure. The Kurz company invented a transfer coating process for fresh concrete. They promise an effective protection, which leads to longevity and enables the conservation of resources for sustainable building.

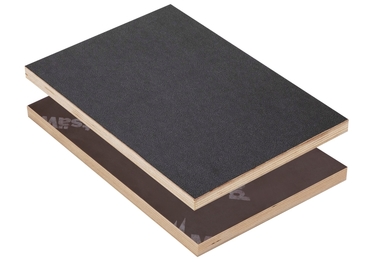

Siporit is based on the idea of creating a nearly pore-less concrete surface. The sealing protects the concrete against the ingress of water, and also against desiccation, efflorescence and frost. The resilience of the concrete components increases eventually. Furthermore, most soiling can be removed with ease, according to Kurz. The surface coating is applied during concreting. Therefore, the formwork is lined with Siporit. Subsequently, concrete is poured into the formwork as usual. After curing, the formwork can be removed without the need of an intense cleaning process or the use of formwork oil. The carrier material may remain on the concrete surface as transport and storage protection, and easily be removed on site. Since the coating protects the concrete from environmental influences, a reduction of the concrete covering could be a possible result. Thus may contribute to the reduction of CO2 emissions. Siporit is currently in its final development phase.

Contact

Leonhard Kurz Stiftung & Co. KG

Schwabacher Str. 482

90763 Fürth/Germany

+49 911 71 41-0