Formwork panels for concrete elements with top-class surface finish

High-quality, sophisticated results in concrete construction essentially depend on the design and quality of formwork systems. After all, like a skeleton, they give the poured concrete its structure. With Metsä Wood Duraform, the Finnish subsidiary of Metsä Group adds a cost-effective and durable option to its range of formwork panels: The maintenance-free birch plywood panels can be reused up to 200 times and make it possible to create exceedingly smooth surfaces while adhering to the concept of a circular economy.

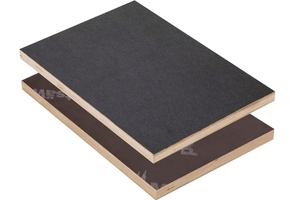

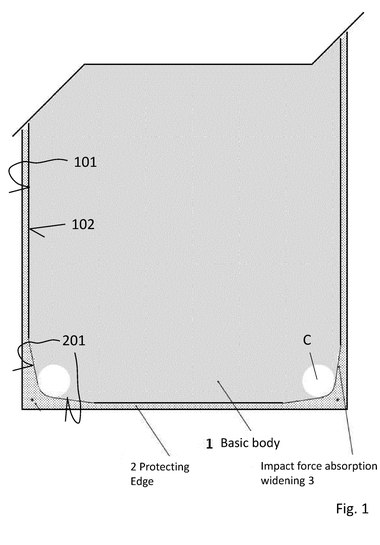

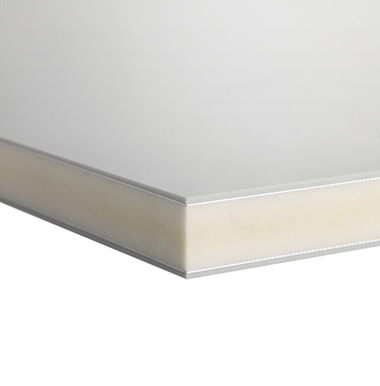

Formwork systems are indispensable when it comes to pouring concrete for walls. This is because they give the poured concrete its shape and enable fast and cost-effective project completion. Despite its low weight, the new Metsä Wood Duraform line of formwork panels excels with its high strength while being largely resistant to deformation. This is why the durable, maintenance-free birch plywood panels manufactured by long-established Finnish producer Metsä Wood are exceedingly easy to process while allowing for a particularly smooth concrete finish thanks to their specially designed surface.

Versatile uses

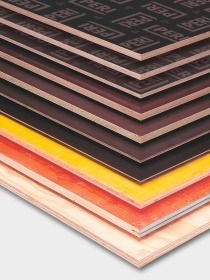

Metsä Wood Duraform panels are available in various standard sizes and thicknesses for a wide range of applications – they can be up to 1.5 m wide and 3.66 m long. Their base is made of resource-saving, sustainably produced Finnish birch plywood, which consists of 1.4 mm thick veneers glued together in a crisscross pattern. The composite coating applied to the concreting side of the panel is moisture-resistant, thus reducing rippling and providing a smooth concrete surface right from the start.

The quality and workmanship of the formwork panels used is crucial for ensuring reliable, high-quality results. Made of heavy-duty birch plywood, the material reduces deflection to a minimum – even for wide spans. This is because, despite its low weight, Metsä Wood Duraform provides particularly high strength levels. Thanks to their specially designed structure, the panels thus allow for significantly leaner, resource-economical formwork arrangements and easy handling on site.

Longevity means sustainability

Concrete formwork is subject to heavy wear and tear due to its use on the construction site. In this context, the tough, scratch-resistant composite surface of Metsä Wood Duraform elements facilitates cleaning and subsequent reuse. Their improved crack resistance and reduced chipping – even when fastened with nails – contribute to a consistently high surface quality. Since Duraform panels can be reused up to 200 times, they prove to be particularly resource-friendly also beyond their life cycle, which perfectly corresponds to a sustainable circular economy.

The latest addition to the Finnish manufacturer’s range of high-performance formwork panels not only impresses with its sustainability credentials, however, but also with its high cost-effectiveness. Metsä Wood Duraform panels thus offer formwork system manufacturers, rental companies and users a meaningful cost advantage over other materials, making smooth concrete surfaces affordable in a wide range of applications – not just for prestigious architectural projects.