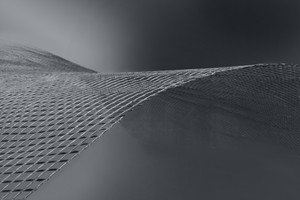

Innovation: Solidian Form

With its Solidian Form carbon reinforcement, the company Solidian aims to set new standards in architecture. The product offers added value in precast construction – from simple angle reinforcements to freeform reinforcements. Uses are especially intended for façades, but also for molded concrete blocks. This modern reinforcement enables an architecture that is otherwise almost impossible to achieve: extremely thin, three-dimensional curved forms of concrete.

The product is offered as carbon reinforcement (CFR) or as glass fiber reinforcement (GFR), depending on the requirements. Variable cutting of the standard products to size can take place in the plant. The concrete can subsequently be cast or sprayed into any desired shape. Especially developed spacers for this are available, as required. Where the maximum crack width must be limited, the reinforcement elements can be additionally sanded. Reinforcement elements from Solidian can, moreover, be used not only in the precast plant, but also on the construction site. In such cases, the formwork is constructed and cast on site. The sustainability of the products should also be emphasized. Currently up to approx. 98 % of the buildings constructed can be cleanly separated by type. The eco-balance, compared to reinforced concrete, is better since less material is required.

Implementation in practice

On the example of a bridge, it was demonstrated that approx. 50 % fewer resources are needed for construction with carbon concrete. That corresponds to savings of approx. 27 % CO2 equivalent. Furthermore, owing to the savings in material, walls can be designed thinner and thus more usable space obtained.

The free forms can be made in one piece from the flat mat, in standard sizes of 6.0 m x 2.3 m. To give them the three-dimensional form, the previously impregnated textile, the so-called Prepreg, is stretched onto a purpose-designed form and hardened in a special oven. The reinforcement is, if required, composed of several elements, depending on the dimension of the architecturally designed form. On request, mats measuring up to 8.0 m x 3.0 can be used. These design options are already being implemented and used in practice. Complex free forms can be realized, such as the Twist of the Cube project in Dresden, the first building completely erected with carbon concrete. The Twist is a three-dimensional twisted element.

Contact

Solidian GmbH

Sigmaringer Straße 150

72458 Albstadt/Germany

+49 7431 10-3135