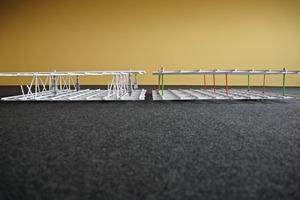

Innovation: company presents cage wall produced in a fully automated process

This year’s edition of the Engineering Days held in Vienna saw a real new launch: Upper Austrian entrepreneur Hubert Rapperstorfer presented the result of more than one year of development work. “At the core of our innovation is the unit that ensures fully automated production of extensive reinforcement cages in any size. This is an absolute novelty that also enables some significant innovations within the precast element itself,” says Rapperstorfer. According to him, this innovative production method simplifies the manufacturing process whilst also enhancing quality.

Visitors were interested not only in the innovative production method but also in the cage walls that result from this proc-ess. “Only seven spot welds per square meter are needed for our cage wall, whereas conventional double-wall units require 44 welds. At the same time, we get rid of more than 90 % of plastic parts. Overall, our customers save a lot of steel, plastic and energy,” Rapperstorfer explains. According to him, despite these savings, precast elements produced using this method exhibit greater structural stability than conventional walls. “We are able to install rebar in the right diameters, numbers and positions – with pinpoint precision, which provides tangible benefits in terms of structural design. This means that we can also increase the concreting speed during construction of the building if requested by the client,” Rapperstorfer adds. He and his team joined forces with Maba, the Austrian precast producer, as the development partner to advance this system to the series production stage. International market entry is set to be the next milestone, starting at the Ulm BetonTage congress.