Innovative Teka mixing technology for plant modernization in the Ehl concrete plant, in Neu-Bamberg, Germany

Ehl AG is a company in the construction materials sector committed to sustainable production of concrete elements. Recently, within the scope of plant modernization at its Neu-Bamberg location in Germany, it has upgraded its mixing technology. For this project, the management at Ehl again decided on a mixing plant from Teka.

Ehl AG is a company in the construction materials sector committed to sustainable production of concrete elements. Founded in 1976, Ehl is now a member of the CRH Group and with 28 locations and with a workforce of around 1,000 (of these approx. 70 at the Neu-Bamberg location). It has served private and commercial customers on the German market, as well as customers of local authorities, and has achieved an annual turnover of around 200 million euros.

The Ehl range of concrete products for garden and landscape construction comprises pavers, curbstones, slabs, walls, palisades, step systems, support brackets as well as street furniture. The products are sold exclusively through selected Ehl sales partners. Ehl does not directly sell to private customers – except for special sales directly from the plant. In its do-it-yourself portfolio, Ehl offers an additional choice of products for DIY, which can be obtained directly from DIY retailers.

In light of the innovations in production processes with energy-saving machines, responsible use of resources as well as continuous optimization of formulations, Ehl, in reconciling quality and the environment, stands for a corporate development oriented towards sustainability.

Within the scope of plant modernization at the Neu-Bamberg location, the focus was in particular on upgrading mixing technology. Ehl management decided once again on a mixing plant from Teka.

Two Teka high- performance turbine mixers with 1.1 m3 output

The Teka turbine mixers differ from conventional mixers in that every mixer can be individually configured. The designation is not – as usual – oriented to the maximum filling level, but is adjusted to the specific application. Accordingly, the drive power, the number of mixer turbines as well as the size of the mixing trough are variable and are adjusted individually, based on the batch mix to be produced.

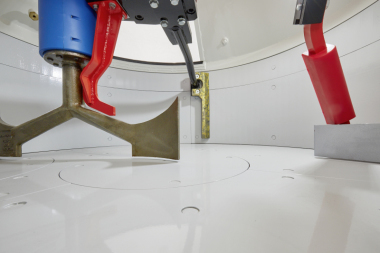

The resulting two Teka high-performance type G-2-V turbine mixers have a maximum discharge rate of 1.1 m³ and a maximum filling level of 1,650 liters and/or 2,640 kg per mix. The 45-kW main drives are generally fitted with a frequency converter. This means that the speed of rotation of the mixer turbine can be optimally adjusted to the mix and is moreover able to process the mix at different speeds during the mixing cycle (for the filling process, dry mixing, wet mixing and discharging, etc.).

These high-performance turbine mixers with innovative mixing technology are fitted with a patented mixer turbine with hard-metal wear lining as well as a counter-current rotating mixer star that ensures highly intensive mixing of the batch constituents without damaging a single particle and therefore without changing the grading curve. The mixer star as well as the likewise rotating discharge and striking paddles continually feed the patented mix turbine with material. All this leads to very intensive and rapid mixing of the material, within very short time, and a high degree of homogenization of the mixing water as well as a nearly linear run of the measuring curve during moisture measurement.

Frequent change of product and color possible

Another reason why the company Ehl decided on a Teka turbine mixer was because this machine type has another advantage over some other mixer types: i.e., the possibility of processing absolute small amounts and minimum quantities. Here, according to the manufacturer, the turbine mixer really comes into its own. Teka turbine mixers are mainly in operation where different and high-quality products are manufactured, and therefore where frequent product changes, including frequent color changes, occur on a daily basis.

Modernization at Ehl was supplemented by a Teka special feeder with tilting bucket, which supplies, via a two-way valve, both turbine mixers with aggregate. This feeder with special design had to be fitted into the existing steel construction and was, accordingly, especially designed and manufactured for the conversion. One of the great advantages of this modernization is that both mixers can alternately manufacture the same products.

In the meantime, the Teka turbine mixer has further become established in practice with many well-known manufacturers of concrete products in Germany, Europe and worldwide. The company Teka Maschinenbau GmbH is one of the leading suppliers of high-performance mixers as well as plant conversions and modernizations, as well as new systems for concrete products and the precast concrete industry. The company, based in the Palatinate region of Germany, can draw on an enormous stock of knowledge and experience, for which the wishes of the customer always come first: “Every project is individually planned and analyzed and the optimal solution for the customer determined. During recent years alone in Germany, many concrete plants were modernized to meet the latest requirements of the customers. The focus is always on satisfied customers and successful processing of plant modernization,” says Managing Director Markus Gartner.

Satisfactory conclusion of all project participants

Two additional partners participated in the project in addition to the protagonists mentioned earlier. Production engineering at Ehl consists in total of two block machines, a retaining wall machine and two finishing systems. The existing machines for concrete block, planting ring and retaining wall production are from Masa and Schlosser, the plant control system from Sauter and the old mixers that were replaced in the course of modernization also from Teka.

Teka Managing Director Markus Gartner is visibly satisfied “Teka Maschinenbau GmbH is a reliable partner for countless customers in Germany and abroad, also in the corona crisis. Teka was able to ensure punctual supply of spare parts to many concrete plants, as well as reliable installation service. Teka is in an excellent position and is also able to keep the concrete plants of our customers running by reacting to future challenges quickly, flexibly and consistently. In this context, the company management and the staff are taking this opportunity to congratulate Teka on its 60th anniversary. They would here also like to expressly thank on behalf of the Ehl Group the many other loyal and valued customers at home and abroad for their support and good collaboration over many successful years. All our customers can continue to expect that Teka will be a competent, reliable and responsible partner also in the future.”

Ehl production managers Lars Steeg, Peter Baumgärtner and Sven Schimbold unanimously expressed their satisfaction: “Neither engineering nor processing gave any cause for complaint. As has been the case already at the first installation of the previous mixing plant some years ago, collaboration with the Teka team around Markus Gartner and Guido Egler was outstanding. Within a matter of weeks, i.e., from the first to sixth calendar week of this year, the entire modernization was successfully completed; the existing technology was dismantled already in December. For this reason, tremendous praise from our side to all participants.”