Laser projection in double-wall production

Con-Form is a group of companies in the construction industry with headquarters in Norway. Several precast production facilities of the group are located in Norway and Sweden – among them a precast production facility for double-wall and floor elements in Strömstad, approximately 150 km north of Göteborg. The plant has now converted its production to be completely supported by laser projection systems supplied by mecoon-Lasertec (Austria). Beginning now, Con-Form will employ lasers in all stations – from reinforcement to final inspection. With the implementation of laser projection systems at all stations, Con-Form expects faster, more precise production of double walls with reduced faults.

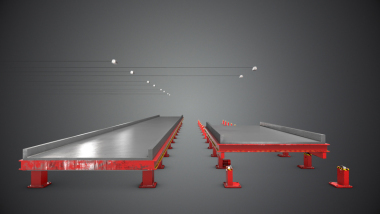

Double-wall production in Strömstad takes place at two tables for the manufacture of concrete reinforcement. Included in the production systems are two lines, each 35 m long, used alternatively, for production of the first shell; a pallet line for manufacture of the second shell; and a folding table for folding the two walls together.

An essential prerequisite for such work with laser projectors is an end-to-end CAD solution. This has been ensured by the PP manager of Nemetschek . The individual stations are fitted with a laser control unit and remote control – via which, adjusted to the given requirements of the stations – the projection objects can be activated individually or in groups.The calibration to ensure precision is designed as sensor technology. All laser projectors are equipped with remote maintenance features, enabling mecoon technicians in distant Austria to directly access the system for troubleshooting in case of malfunction. Laser projectors in need of replacement can be easily exchanged by the employees directly in the plant.

Reinforcement

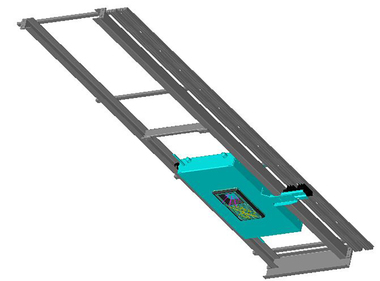

This station manufactures the reinforcement cages, together with nearly all embedded parts to be installed later. For suspension of the steel mesh and the lattice girders, the laser line projects both the length and width as well as the height of the projecting rebar steel and the concrete cover. Accordingly, all reinforcing steel components can be cut exactly at the laser line shown. The laser likewise shows the target position of the embedded parts to be installed in the reinforcement. The embedded components are fixed to the reinforcement cages using wires. This process also takes into consideration the respective position of the embedded part in the wall – the installation height of the embedded part. (Fig. 1).

The content of the projection is so configured that the workers at all times receive all the information on the various working steps in the manner to which they are accustomed. The control of the project content can take place conveniently here, directly on the surfaces pro-cessed.

Production of the shells

The shells are manufactured on two lanes, each 35 m long (Fig. 2). Four laser projectors are mounted above each of the two lanes. Many elements are simultaneously displayed here. The lane is as a rule already occupied before work is scheduled. If required, the workers can move individual elements on the laser control without losing the content of the drawing. As on all stations, only the contents that are actually required are displayed. For example, all electrical conduits are hidden and only the socket outlets on the side of the first wall displayed. Only later, following installation of the reinforcement cages, are the wall outlets of the second half of the wall displayed to allow double-checking of their correct position and completeness.

In order to distinguish the many different elements on the production table, the designation of the element – here a three-digit number – is displayed in a corner of the elements. This also facilitates the subsequent installation of the reinforcement cages.

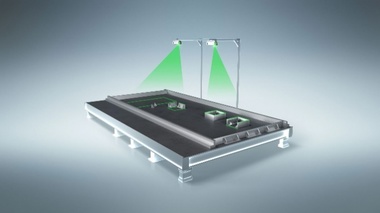

Following the casting process, the laser enables a very quick check. While the concrete is vibrated-in, the formwork can be shifted. With the aid of the laser, any deviations that occur immediately become apparent. The laser system for this process is also operated directly at the work table. The PC that controls the laser is located at the head of the long lines and may be operated only for adjusting the production data. Accordingly, the control unit (Fig. 4) does not need to be manned while the individual work steps are carried out. Production of the second shell takes place on a conventional pallet. Here, two laser projectors project the contours and the blockouts (Fig. 5).

Turn-in with the folding table

The pallet is first placed on the folding table. In this position, two laser projectors display the blockouts and the embedded parts on the fresh concrete so that the concrete in these places can be removed (Fig. 3). Following the folding process, the first shell is precisely aligned above the second shell at the desired height via laser projection.

Insulation

Con-Form also prepares the insulation for the partition wall on a station specifically dedicated to that purpose. The insulation layer between the two halves of the double wall is already taken into account by the CAD system, so that it can be further processed by the laser control software during production. For this purpose, every double wall is subdivided into the appropriate number of layers. Here, too, the laser control software is configured such that that workers obtain the desired laser projection by means of a very simple procedure with a good overview. All data of no relevance for this station are removed in advance and can be accessed at any time for checking. Element after element can be processed in only a few operator control steps. This type of prefabrication for insulation bodies is, however, still in its first stages of development and is being continuously developed further. This requires a high measure of flexibility, which is in any case necessary for both the laser projectors and the control software.

Summary

By its implementation of laser projection, beginning with reinforcement installation and proceeding to the complete double wall, Con-Form has succeeded in considerably increasing production output, minimizing at the same time the error rate. Its flexible laser project software, which can be effectively expanded, enables rapid adjustment of production to the future requirements of the market. With this laser projection technology, comprehensive improvements on all positions of the production can be achieved with comparatively low capital investment. ¢