Lautern Barrier – Innovative Self-Closing Flood Protection System from UHPFRC

The Department of Concrete Construction and Structural Design at TU Kaiserslautern developed an innovative flood barrier that is self-floating in water, wedges itself on its sides and thus automatically prevents flooding.

The relevance of flood protection is increasing significantly, not least owing to the effects of climate change. Flood and heavy rainfall events cause considerable damage to real estate and public infrastructure. This is why the European Flood Risk Management Directive provides a framework for mitigating the adverse effects of flood events on human health, economic activities, the environment and cultural heritage [1]. Its clear focus is on flood prevention, including the installation of appropriate protective structures. Flood protection measures are currently often based on mobile protective systems whose installation is relatively complex. In practice, such systems can generally not be provided to the required scope and at the necessary erection speed, particularly in the case of heavy rainfall events with short early warning times [2]. This is exactly where the newly developed, innovative, self-closing precast flood barrier consisting of ultra-high-performance fiber-reinforced concrete (UHPFRC) comes into play. This system requires almost no maintenance while providing safe protection against flooding and a long service life. The new barrier system is primarily designed to protect buildings, for instance at their entrances, driveways into underground parking facilities, or embankment promenades, as well as to create temporary retention space on inner-city streets and squares.

Design principle of the self-closing UHPFRC flood barrier

Both in Germany and in other countries, such flood protection systems are usually designed with metallic or textile elements associated with disadvantages in terms of their reliability, cost, and range of applications. At TU Kaiserslautern, a BBR research project [3] was launched to develope an optimized solution. An innovative design principle was developed that uses high-density, filigree elements consisting of ultra-high-performance concrete (UHPC) in a sandwich construction that is cost-effective, robust, reliable, and durable.

The protective elements should float automatically without requiring additional technical support, functioning independently of a potentially interrupted power supply or emergency services. The core of the protection system are the floating sandwich elements, each with a thin top layer of UHPC, a core of extruded polysterene rigid foam, and a specially designed watertight concrete joint. These features were developed at TU Kaiserslautern and break new ground in the field of concrete construction. The particular benefit of this system lies in the fact that it can be precast as a single, coherent element, thus allowing for its production in large numbers.

The development process centered on the idea of capitalizing on the effective mechanical properties that sandwich elements provide at a low unit weight. The use of UHPC ensures a dense surface structure with an ideal formability of the surfaces and low friction loss. The latter factors were of particular importance for designing the watertight concrete joint that connects the rotatable, floating barrier with the stationary foundation.

Applying this design principle, development work was divided into two steps: Firstly, an innovative, self-closing system was to be developed featuring an optimized concrete joint zone creating the connection between the barrier and the foundation. Secondly, the structural capacity of this system had to be optimized in order to resist the potential loads both in the passive (traffic loads) and the active state (water pressure).

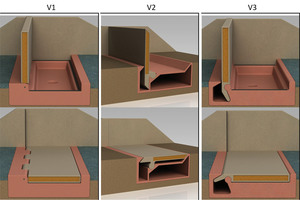

Initial system designs differed in the detailing of the joints connecting the barrier with the foundation in its passive and active state. In Variant V1 (Fig. 3), the connection was established through a metal axle in a “mortise-and-tenon” pattern as commonly used in timber structures, which provided the benefit of easy formwork placement and assembly. Yet there were also disadvantages, such as potential steel corrosion and the sealant to be applied in the joint area. Variant V2 (Fig. 3) was to overcome these shortfalls by designing the joint as two sliding surfaces in a swivel arrangement ensuring a tight fit. In this design, the barrier links to the foundation through a cylindrical surface that turns around a precisely fitting sleeve. However, the stability of the barrier in its active state continued to be problematic because of the large critical forces acting on the joint area. The final design, Variant V3 (Fig. 3), resolved this issue by reducing the mass of the barrier and ensuring firm anchoring in its vertical position.

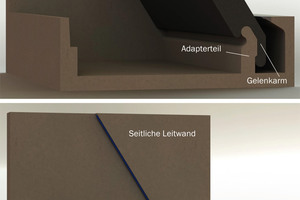

Variant V3 was identified as the most appropriate solution, and optimized further. The first optimization step involved a modification of the joint (i.e. the joint arm and adapter part) and a limitation of the barrier’s rotation to an angle of 60° so as to ensure that it again lowers into its passive state as a result of its own weight when the flood recedes. Further steps included the addition of a lock securing the barrier against vertical forces acting in its active state (water pressure) and of a limit stop whilst also adjusting the dimensions of the entire system (Fig. 2).

Development and testing of small prototypes

After completion of the comprehensive theoretical studies on the optimization of the design principle, the barrier and the foundation were pre-dimensioned for the relevant load cases and material characteristics. In this process, the same micro-reinforcement as in the preliminary tests of the sandwich elements was used [4]. The foundation was reinforced with conventional steel rebar. The related calculations and analyses resulted in a total height of 21 cm for the sandwich element of the barrier, including a 2.5 cm UHPC cover on each side, and a 10 cm thick adapter part connecting the barrier with the foundation in order to resist the forces acting at a flood level of up to 100 cm, including traffic loads [5].

Initial experimental tests were carried out on prototypes to investigate the structural capacity and deformation behavior of the system. For these tests, a full-size, 20 cm wide barrier was produced complete with the joint arm and adapter part. This prototype was then subjected to quasi-static and dynamic loading in its passive and active state. The series of experimental tests proved that the structural capacity of the newly developed, self-closing flood barrier was sufficient both in the passive state under traffic load and in the active state under water pressure [3]. In addition, the functionality of the new system was tested and confirmed on a consistent test stand [3, 5].

Further optimization steps were implemented in a follow-on research project because the prototype production process still left room for optimization. Within the EU-funded Brigaid project, efforts concentrated on identifying the optimal reinforcement and modality in order to ensure the envisaged structural capacity, easy workability, and simple production. For this purpose, a full-size demonstrator was designed and built at the campus of TU Kaiserslautern. Four series of six 20 cm wide prototypes were produced to investigate the use of micro-reinforcement, reinforcing mesh and steel fibers and to perform bending tests to examine the structural capacity and deformation behavior of the system in its passive and active state.

The most appropriate reinforcement option identified in the project included 2 vol.-% of steel fibers (lf = 12.5 mm, df = 0.2 mm, Fstm = 2,800 N/mm²) and was suitable for use both in the barrier and in the foundation.

A fine-grained UHPC based on Nanodur supplied by Dyckerhoff was produced to ensure optimal consistency for mixing with steel fibers without triggering sedimentation. Its mean compressive strength fcm amounted to 140 N/mm² at a fiber ratio of 2 vol.-% and to 130 N/mm² without fibers. The UHPC reached a mean flexural bending strength fctm of 22 N/mm² (post-cracking with fibers) and of 13 N/mm² without fibers. Styrodur XPS 5000 CS supplied by BASF was used for the 16 cm core of the sandwich structure chosen for the self-floating barrier. A firm bond between the concrete and the core was ensured by 10 mm wide, 5 mm deep grooves milled into the top and bottom sides of the core 28 mm apart from each other.

Development and production of full-size elements

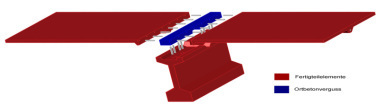

The results of the small-scale preliminary tests were subsequently used for producing all full-size components of the demonstrator (i.e. the barrier and the foundation) from ultra-high-performance fiber-reinforced concrete (UHPFRC) without any discrete reinforcement. The full-size demonstrator was 330 cm wide and 205 cm long; it comprised two identically designed systems, each including a 150 cm wide barrier and foundation and two enclosing lateral walls. The design included the production of stationary elements, such as the foundations and enclosing lateral walls, according to a segmented construction with the required openings. Furthermore, the demonstrator design ensured a non-slip profiling of the barrier surface to allow for the safe passing of vehicles, snow clearance, protection against dirt, and easy flushing of the system for cleaning purposes after the flood event. Besides the full-size demonstrator, additional components were produced for investigating the load-bearing and deformation behavior of large elements.

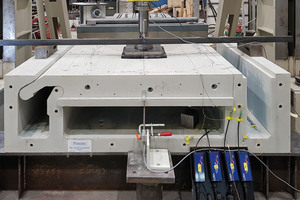

The partially complex shape of the joint within the barrier and the foundation required the milling of highly precise form inserts made from ureol (a polyurethane-based, microcellular material for model-making), which were then fastened inside the securely stiffened wooden formwork. Three threaded rods were used to fix the core to the formwork bottom in order to resist concrete buoyancy (Fig. 4). Both the barrier and the foundation were cast in vertically positioned forms. The fiber-reinforced concrete was poured into the form at the end of the joint arm and adapter part so that it could flow and spread evenly along the cross-section of the barrier and the foundation. This concrete pouring method ensures the most effective dispersion of fibers into the components’ tensile zones [6]. The enclosing lateral walls were cast in horizontal forms, with the fiber-reinforced concrete poured over the top wall edge according to the same principle (Fig. 5).

Experimental tests on full-size elements

Simultaneously with the prototype testing scheme, three-point bending tests substituting traffic loading were performed on the full-size elements in their passive state (Fig. 6). The first specimen was statically loaded to failure, the second specimen was subjected to five cycles and statically loaded to 50 kN and subsequently to failure. A 50 kN load is equivalent to the maximum traffic load in urban areas and to the wheel load of a firefighting vehicle. The tests proved that cyclical loading caused only a minimal plastic deflection of about 0.5 mm in the center. The fracture load amounted to 200 kN at a deflection of about 20 mm. The load-displacement curve was approximately linear up to about 100 kN, with first cracks occurring under a load of 80 kN. The punching failure mechanism occurred in the upper cover layer upon load application. Overall, the test results confirmed the robustness of the system under high loads.

Assembly and test run of the full-size demonstrator

Towards the end of 2019, the full-size demonstrator was erected at the campus of TU Kaiserslautern in the final phase of the project. This process involved the placement of the precast foundations on a previously prepared subbase. Steel rods were used to insert the enclosing lateral walls into the corresponding openings, and the structural segments were tensioned (Fig. 7, 8). A silicone sealant was applied to all joints. Prior to the installation and use of the barrier, high-pressure grease was applied to the contact zone of the joint between the barrier and the foundation in order to reduce friction and to ensure water tightness. In the final step, the demonstrator was filled with water, and its structural capacity was successfully proven under realistic loading (i.e. a truck driving over the surface) (Fig. 10).

Conclusion

The above-described innovative, self-erecting precast flood barrier made from ultra-high-performance fiber-reinforced concrete makes a major contribution to mitigating flood damage. Production and testing of a full-size demonstrator under realistic conditions proved that the flood barrier developed at TU Kaiserslautern meets all requirements in terms of functionality, durability, and structural capacity. The individual development steps showed that the chosen design composed of a sandwich element with UHPFRC covers is ideally suited for precast production, which also ensures the low-maintenance use of the system, particularly of its watertight concrete joint. It would thus be desirable for the system to become commercially available after further testing.

Acknowledgements

We thank the Federal Office for Building and Regional Planning (BBR) and the Brigaid EU project for their funding, as well as BASF for having supplied Styrodur and Dyckerhoff for having supplied Nanodur. We also thank the Department of Hydraulic Engineering and Water Management at TU Kaiserslautern for their support in the field of flood management.