London’s Riverwalk energetically planned of high quality

At the heart of London, on the north bank of the River Thames, there are the three historic embankments, namely the Chelsea Embankment, Victoria Embankment and Albert Embankment. They result from extensive construction works carried out at the end of the 19th century when marshland was drained, the river was made narrower and large new development areas were gained in one of the largest engineering achievements of the Victorian era. Now, almost 150 years later, many of the existing buildings which have characterized this area for a long time shall be replaced. The rehabilitation program includes extensive residential construction projects as well as promenades and park areas, as the huge Riverwalk residential complex located right on the river, for example.

Riverwalk consists of two organically shaped buildings with seven and seventeen stories, respectively, where 116 apartments and penthouses of upper standards are to be found. The curved façades of the building are decorated with a horizontal band of limestone alternating with ceramic panels and glass bands. The limestone band starts on the lower edge of the balconies so as to create a consistent organic shape.

Thermal break against thermal bridging

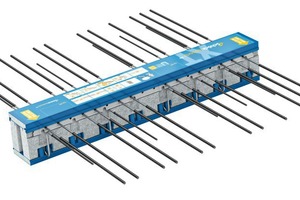

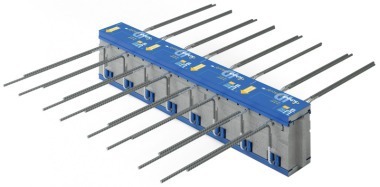

Because of the very high stan-dard of the apartments, the parties involved took the question of how to prevent thermal bridging on the crucial transitions to the balconies into consideration at a very early stage. Thermal bridges violate the British construction regulations, increase the risk of mold formation and the associated health complaints caused by respiratory problems and result in increased loss of energy. In order to minimize these risks, the Schöck Isokorb XT element was used as a structural component for thermal insulation in the entire Riverwalk building complex.

Improved thermal insulation performance

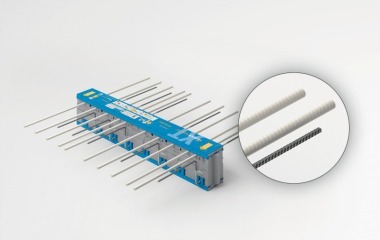

The improved Isokorb XT element allows meeting the increasingly stringent EU guidelines. In this way, it is possible to react to the immediate needs for higher standards regarding zero-energy buildings. Moreover, the applicable requirements of the local building law in Great Britain are quite challenging, and never before an improved thermal insulation was more in demand.

The latest Schöck Isokorb XT element meets this demand and alters the limits of what is technically feasible due to the fact that it is made of the compression module HTE-Compact with high-density micro-fiber reinforced concrete. In addition, the insulation material has a thickness of 120 mm, thus featuring an outstanding performance. This load-bearing element for thermal insulation can be used to design cantilever balconies and transfers negative moments as well as positive transverse forces.

Isokorb XT sets new standards

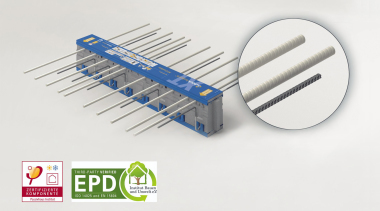

The Schöck Isokorb XT element was certified as a passive house component by the German Passive House Institute in Darmstadt. The certification of the British Board of Agrément (BBA) has similar importance in the United Kingdom. BBA is an independent, non-profit organization supporting manufacturers and installation companies to enhance their professional skills and create clarity throughout the industry by means of stringent test procedures, inspections and certifications.

The certifications and inspections are carried out by teams with comprehensive professional skills and are largely recognized by building designers, construction supervision agencies, local authorities, insurers of the industry and the most important building trade associations. The latest Schöck Isokorb generation has set new standards of certification which resulted in the fact that BBA has developed a new certification method with higher requirements and test criteria.