Mobile battery mold for complete Building systems

Rapid population growth and the increasing urbanization are some of the main challenges of the 21st century. This calls for more and faster construction of large residential complexes. However, major construction sites for the construction of new residential districts or entire cities have a temporary nature and generally do not allow the erection of conventional stationary precast concrete plants in the close vicinity to the construction site. Central precast concrete plants, in contrast, often have the problem that the route of transportation is too long and complicated, especially in far remote or highly congested areas.

Weckenmann Anlagentechnik GmbH & Co. KG, Dormettingen (Germany), has now presented a solution to this challenge by developing a mobile battery mold for the vertical production of precast concrete elements in the close vicinity to construction sites.

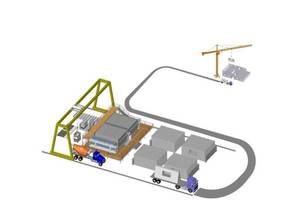

Components of the

field factory

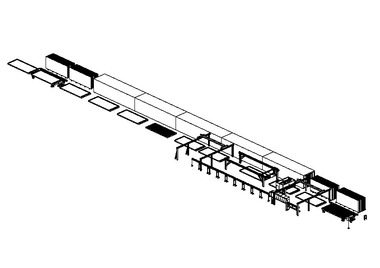

According to this technical

solution, a battery mold is mounted up on a special vehicle such as a semi-trailer that can be moved by a common tractor. The special vehicle serves to transport the heavy central and external molds. These central elements of the battery mold as well as other plant components such as the control unit, the heating system and the hydraulic unit are mounted on the special vehicle in a fixed manner. The additional working platforms, the intermediate molds and other small-scale plant components are transported by conventional vehicles from construction site to construction site.

In addition to the mobile battery mold, a suitable lifting gear is required. This equipment, for one thing, is needed for setting up the battery mold, however, will also be used for all other load movements necessary in the ongoing production process – starting from the removal of the finished concrete elements from the battery mold to the conversion of the mold and the bringing in of the steel reinforcement right up to placing the concrete by means of a crane buckets.

This task can be assumed by a gantry crane, a conventional rotating tower crane or a mobile crane. The gantry crane requires a runway being based on strip foundations or on transportable foundation beams. If required, the special vehicle is furnished with a heating system fueled by oil or gas, which is providing the battery mold with hot water. A mobile tent running on the crane runway can protect the battery mold against extreme weather conditions, when necessary.

According to the supplier, only about 5 persons are needed for assembling and dismantling a complete field factory within a few days.