New Sono W/C with Bluetooth, GPS location and BIM

The measuring probe for determining the water-cement ratio already presented for the first time at bauma 2016 has recently been further developed. Apart from the electronics, the new feature is the wireless interface to the mobile terminal unit. This facilitates allocation of data points and measurement series by GPS. A supplementary photo of the installation situation or of the delivery note and/or delivery vehicle can be stored or sent, if necessary. The further development of the instrumentation, however, was aimed not only to achieve wireless linking, but also to obtain shorter measuring times – as well as still steeper measurement edges that would offer more precision for special formulations. The Sono W/C is a success story. In 2021, the Korean KCI proposed its use for standard continuous monitoring of fresh concrete as standard procedure. The system has experienced highly intensive demand around the world – wherever uninterrupted monitoring of construction sites is required.

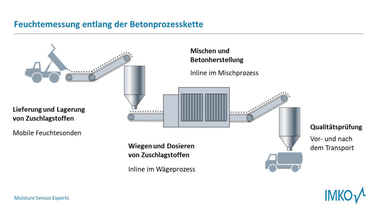

The technology leader Imko belongs since 2017 to the Endress + Hauser Group and is worldwide at home in the construction, soil and bulk materials sectors. Imko manufactures its instruments manually in Ettlingen, Germany, and also manufactures, in addition to the measuring probe presented here, sand and gravel probes for monitoring preliminary steps in fresh concrete production. With its small but excellently interacting team of only 20 persons, the company Imko Micromodultechnik GmbH is now successful worldwide in its persistent further development of innovation in its products.

Patented Imko measuring principle

The technology incubator already notably improved the precision of the Sono W/C three years ago by employing advanced subassemblies in the probe. A new semi-conductor chip resulted in improved coupling and uncoupling of the high-frequency measuring signals, which now, with perfected calibration leads to still more precise measurement results throughout all metrological situations. These systems achieve precision of up to ±3 l/m³ with specific formulation comparison. Sample precision is accordingly already surpassed during drying, which results in additional considerable time savings of approx. 90 %. In particular, for monitoring the construction of motorways, aircraft movement areas and tunnels made of concrete, the speed and reliability of the methods used are essential for their success.

Determination of the W/C ratio for fresh concrete takes up considerable time in the daily routine of construction laboratories and supervisors. With the new generation of measuring instruments, additional reference points distributed over the complete range of the dielectric constants are now used and the mean straight line is replaced by a fifth-degree polynomial curve. That is possible because the patented Imko measuring principle maps its measurements over the entire range of dielectric permittivity (air = 1 to water = 81). According to the manufacturer, this is a unique characteristic and results in great measuring accuracies compared to other technologies.

This also satisfies demanding customers such as Gebro Oegmen, Division Manager for Technology at Beton Kemmler in Tübingen. “This is exactly the right instrument – and we won’t give it away. Although reference methods, by comparison, take a great deal of time, the Sono W/C provides the same measuring values in no time at all.”

CONTACT

Imko Mikromodultechnik GmbH

Am Reutgraben 2

76275 Ettlingen/Germany

+49 7243 59210