New anchorage set for flexibility and seismic protection

They occur, unfortunately, nearly daily around the globe: earthquakes. Tremors with strengths that endanger humans and buildings occur three times every week on average. Measures for earthquake protection of buildings are therefore essential in many regions and are regulated, in Germany, by DIN EN 1992-4.

In case of earthquake, cracks occur in concrete. This gives rise to the danger that the shear bond between anchor and pipe cracks and the fixed-in-place object – for example, a high-bay storage system – becomes detached from the anchorage and collapses.

The fastening solutions for earthquake protection

In April 2022, the anchorage set from Robusta-Gaukel – specialist for erection, anchorage and safety technology as well as for demanding special solutions – passed the strictest test and received C2 approval from the regulatory authority for the highest loading level of buildings. This covers cracks up to 0.8-mm width.

Accordingly, this solution provides the maximum possible protection for buildings and humans in an earthquake event. The damaging effects of earthquakes can be considerably mitigated. This anchorage set has been successfully used even in earthquake-plagued Naples: the challenge here was to fix in place the high-bay storage system in a factory hall to make it earthquake resistant. The fastening solution has been proving its stability there since 2015.

The set is designed for use with anchorages of all kinds: from steel structures, to high-bay storage systems in silo construction, to machines and precast concrete components. Leaving room for flexibility: precise calibration is necessary after only completion of the unfinished structure.

The Robusta anchoring set enables not only earthquake-resistant building, but moreover offers another bonus: flexibility.

The usual challenges faced on construction sites are known: the dowels are embedded in the concrete, but sometimes weeks or even months go by before steel construction workers begin their work. By that time, parts of the projecting dowels have been run over by construction machines or changes to the structural drawing made. If, for example, the anchorage points of the steel columns now lie somewhat farther apart than originally planned, composite anchors must be subsequently drilled into the concrete. There is the risk that the dowel during this process comes into contact with the reinforcement and severs it. This weakens the reinforcement in the ground slab and consequently negatively influences the loadbearing capacity.

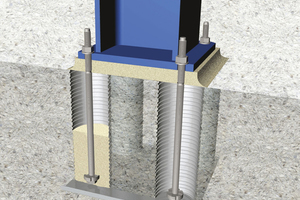

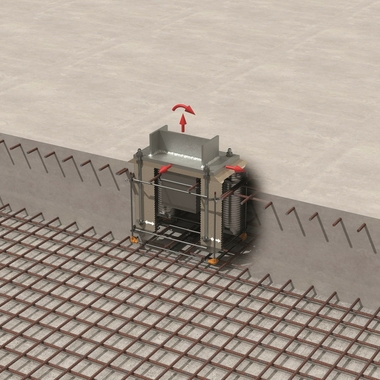

The anchorage set is the perfect connecting link between the rough concrete structure and the structural steel work with significantly closer tolerances. The great advantage: the anchor rods with anchor plates are precisely calibrated and cast into the pipes only after all carcass work has been completed. In the first step, only the profiled sheathing pipes are cast into the ground slab or into the foundation, leaving a practice-oriented installation tolerance of up to 10 cm. Therefore, should the anchor pipe slightly shift, this presents no problem due to the tolerance in the pipe. The dimensions of the pipes and the anchor plates are inter-coordinated such that a tolerance of ± 1.5 cm or more is available.

The complete package from one supplier

The set includes installation aids and templates, markers and grouting mortar. Improvisation or complex self-built template holders are unnecessary. The dimensions and the forms of the anchorage set can be optimally adjusted to the given load combination.

With the especially developed and newly revised Dimensions EQ design program (EQ stands for earthquake) and the relevant DXF or DWG files, the placement of the anchorage set can be simply calculated by Robusta.

The practice-oriented anchorage set therefore satisfies not only the specifications for earthquake resistance in accordance with C2, but also enables maximum possible flexibility at the construction site.

CONTACT

Robusta-Gaukel GmbH & Co. KG

Brunnenstr. 36

71263 Weil der Stadt (Hausen)/Germany

+49 70 33 53 71-0