Safe storage of wall elements on the construction site

Intermediate storage of thirteen meter high wall elements with large glass fronts? Not so easy. A solution is needed that keeps the elements stable and thus ensures order and safety on the construction site. At the INCUBA Research Park in Aarhus, Denmark, the construction company A. Enggaard A/S relies on the DepoFlex Storage Rack from Robusta-Gaukel.

IT campus in Denmark grows

The research park is currently being expanded by 18 floors and 22,000 square meters. Construction started in February 2022 and is scheduled for completion in summer 2024. The INCUBA Next extension complements the existing INCUBA Katrinebjerg, which already houses 70 specialized IT companies. This will create a unique IT campus for students, university staff and companies.

Safe intermediate storage

Rene Behnsen, foreman at A. Enggaard A/S, reports on the challenges of the large-scale project: „INCUBA Next is designed as a sustainable building with DGNB Gold certification. During construction, the latest standards are applied in terms of sustainability, flexibility and comfort. The building elements are correspondingly high-quality and large. This calls for the utmost caution, even during delivery. It is often not possible to assemble the parts on site directly from the vehicle. If I would simply lay the wall elements on the ground or lean them against a wall, there would be a great risk of damage even with wall elements of normal height - this is unthinkable with our 13-meter-high elements weighing up to 15 tons. With the DepoFlex Storage Rack from Robusta-Gaukel, we have found an optimal solution that ensures order and safety on the construction site. Therefore, we have ordered a total of 5 pcs Depo-Flex 6000 and 10 pcs extensions for the expansion of the IT campus and will also rely on the Storage Racks from Robusta-Gaukel for future projects.“

Quickly assembled and transported

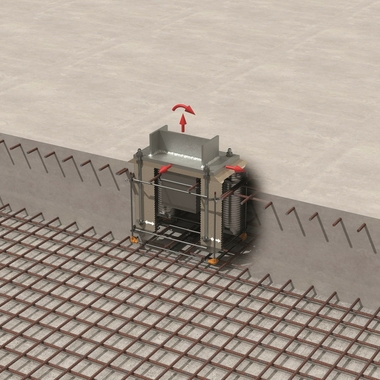

Without special foundations, the DepoFlex can be set up anywhere on firm ground; no additional anchoring necessary. The storage rack can be quickly dismantled to save space with storage and transportation. With stable suspension eyes, the empty, assembled storage rack can be easily lifted and moved by crane.

The DepoFlex storage racks make a frame shaped, complete structural system in themselves, which are stabilized by the weight of the wall elements on to the lateral wooden girders. These girders support the construction elements integrated into the ground frame and protect the sensitive edges of the prefab elements against chipping off.

Also up to big challenges

If – as in the project in Aarhus – 13 meter high precast elements and wall formwork are to be stored, the DepoFlex is increased to 6.60 meters with two extension elements. For standard-sized elements, for example, the Depoflex 4000 is used, which allows storage of elements up to a height of approx. 4 meters. In addition to high precast elements and wall formwork, the storage rack is also suitable for low panels, such as embankment elements. The intermediate storage system for precast wall panels can score points both on the construction site and in the precast plant.

Competent on-site support

A Danish sales partner of Robusta-Gaukel, the company Brunsgaard A/S, a specialist in the fields of scaffolding, formwork and lifting platforms, took over the sales handling in Denmark for the IT Campus. The partnership of Brunsgaard A/S and Robusta-Gaukel offers great construction site equipment service and technical support in Denmark.

CONTACT

Robusta-Gaukel GmbH & Co. KG

Brunnenstr. 36

71263 Weil der Stadt (Hausen)/Germany

+49 70 33 53 71-0