New developments in magnet shuttering

Ratec, founded in 1994, has established magnet shuttering in precast concrete production and has been a key driver of this technology for over 20 years. At bauma 2016, Ratec presented their latest solutions in the field of magnet shuttering, which were developed with the objective of further improving plant use. In close cooperation with users from the field, the product innovations were rendered suitable for real-life application.

Precast producers are facing ever-increasing requirements to continuously develop and improve their offer and range of products in order to maintain their success in the competitive marketplace. Developing new and improving existing shuttering solutions provides them with the support they need to master these challenges.

The central question to be posed in many cases is how to achieve maximum flexibility and economic efficiency while minimizing the use of economic and human resources. Three solutions offered by Ratec are presented in detail below.

MST – multipurpose carrier for standard solid elements

The MST modular shuttering carrier originated from the desire to offer a simple, versatile, flexible and lightweight system that would be able to cover numerous different shuttering requirements. The MST shuttering carrier is a multipurpose unit suitable for the production of wall and floor elements at thicknesses ranging from 100 mm to 500 mm. The system combines the benefits of various other solutions as it is flexible in both length and height, is comprised of fewer single parts, and impresses with its low weight and ease of handling. The shuttering carrier is secured at the SPB 2100 magnet box by means of a clamp and serves as a base for mounting wooden formwork or front plate. Flexibility is just one of its numerous advantages:

Being a lightweight component, it has been optimized for manual handling. Weighing less than 21 kg over a length of 3 m, it remains below the standard set by the Employer‘s Liability Insurance Association and relieves plant staff

The MST shuttering carrier is stackable, thus enabling customers to realize virtually all element thicknesses with a single carrier height.

The shuttering carrier is suitable not only for use on one side but can additionally be coupled to allow two-sided use. This feature saves space on the pallet and simultaneously reduces the work effort.

The outstanding static properties tested at the precast plant and exceptional versatility of the MST shuttering carrier turn this new development into a true multipurpose component.

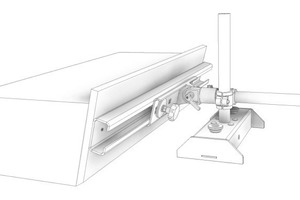

UAR for upstands at any specified angle and continuous reinforcement

The new UAR (short for universal adapter) is yet another all-rounder and, to date, the only known system of its type. It enables upstands to be created at any specified angle, which customers were previously usually required to produce on an individual basis. The system is also suitable for elements comprising continuous reinforcement and stepped upstands. The pivoting arm can be continuously adjusted in both height and distance while being securely fixed at the same time. Steel or wood can be used as formwork facing and is secured by means of the C-rail. A patent application has been filed for this unique product development. Further applications are in the testing phase.

RT U60 Pro adapter –

added value for filigree shuttering systems

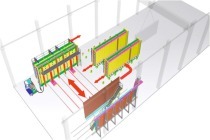

An adapter enabling solid elements to be produced using filigree shuttering has been developed for specific use by the producers of filigree slabs and double walls. It is exceptionally suitable for the production of partition walls using the existing shuttering.

The adapter is used to set up filigree shuttering systems and is secured on the form quickly and reliably by means of an intelligent “keyhole” solution. Wood can be bolted on to serve as formwork facing. Alternatively, wood and fiber-concrete upstands can also be secured by means of a hold-down feature.

In addition, calibration of the shuttering can be dispensed with when using a shuttering robot. Potential future applications could include window block-outs for double walls which can be realized quickly and easily using this adapter.

These product innovations are merely examples of Ratec’s extensive development work. New developments are often initiated by specific customer needs. The objective is always to translate customized solutions into standards that work in different regions and across different plants, yet perfectly comply with individual customer-specific requirements.