Innovations in formwork technology – material-saving, reusable, resource-efficient

Dwindling growth forecasts, strained supply chains and escalating material costs – new (and old) challenges place heavy demands on producers in the precast concrete industry. Ratec, from its base in Hockenheim, Germany, supplies formwork solutions for precast concrete manufacturers. The company is in close contact with its customers and has its finger on the pulse of the industry. This article shows what answers Ratec can offer for contemporary core issues, whilst providing an insight into the latest innovations and advances in the field of formwork technology.

In general, ideas are needed that contribute to more resource-conserving and efficient production processes, whilst at the same time bearing quality in mind. Material-saving formwork solutions offer answers in this regard. This also implies enhancing the durability, reusability, and flexibility of formwork components still further between different projects.

Flexibility through modular system

A good example for this is the 3D mould kit developed for the production of room modules. This type of mould is characterised by its convertibility to other sizes for other projects, which allows it to be used flexibly in the long term. Four molds of this type were installed together with a turning station for a new PBU (Prefabricated Bathroom Units) production in the Philippines. In addition to developing and optimising the mold solution, the installation planning focused on optimising crane times, for example, by intelligently aligning the molds towards the turning station, and to generally minimise process losses in the various working steps. A total of 63 positions are available for the interior finishing and the completion of the bathroom pods. In this project, it was determined that, compared to conventional molds installed on a project basis, the use of the 3D mold kit improved efficiency up to 77 percent in man-hours, and increased the speed by 64 percent, in terms of the total time for completing a sanitary cell.

Magnetic formwork solutions for the horizontal production of flat precast concrete elements, which reduce plywood and expanded polystyrene (EPS) consumption, also help to conserve resources and produce more efficiently.

Magnet shuttering instead of EPS

One of those solutions is a recess box that scores points as a sustainable alternative to EPS. It is used for pipe and duct openings when producing girder slabs and double walls. The recess box is based on the SPB Standard Pro Magnetic Box by Ratec with integrated magnet and automatic component. It is 6 degrees conical for easier stripping and can be produced with or without chamfer. Demonstrable savings of up to 60 % of EPS can be achieved with this box.

Reducing the manual effort required to set up shuttering is another important aspect to consider when developing new shuttering solutions. This ensures consistent quality and less susceptibility to errors, whilst ultimately also giving greater satisfaction to the production team. Such solutions additionally enable faster processes and thus higher productivity.

Focus on reusability

One example in this area is a new window system developed on the basis of robot-compatible SAS Standard Automatic Shuttering. The new window system consists of siderails in standard lengths of 450 mm and 1,350 mm. The siderails have integrated, switchable magnets, as well as mounting knobs that can be adapted for common shuttering robots. They can be positioned by robot or by hand and supplemented by plywood pieces, that are attached to the siderails with small, easy-to-mount adapter plates. These plywood filler pieces can be reused for other intermediate spaces of identical size. As a result, the customers can dispense with EPS and work with reusable components instead. The solution combines automated shuttering logistics and manual works, which provides the customer with flexibility regarding sizes, while at the same time permitting a general reduction in the use of EPS for filling shuttering gaps.

Savings on time and material

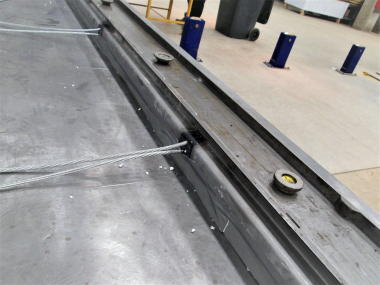

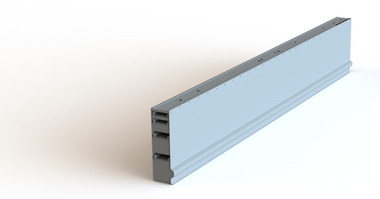

Another example for the simultaneous reduction of material and time is an extension for the universal plywood beam (MST). It has been supplemented by a bracket adapter for the realisation of solid upstands, which allows a significant reduction of plywood. In addition, the MST itself offers high dimensional accuracy, less assembly effort and easy handling.

The new accessory has many advantages for the users:

significant reduction in plywood consumption compared to in-house solutions;

fast assembly;

more precise results thanks to accurate setting options for 90°angles and stabilisation using a C-profile;

for users who are already using MST, the upstand is a logical and lean addition;

the width of the upstand is continuously adjustable from 80–210 mm and the height is also continuously adjustable from 80–350 mm.

The solutions presented as examples here demonstrate that, when new, advanced developments in the formwork sector are thought through holistically and are closely oriented to customer needs, they often solve several problems at once, be it material savings, reusability or reduction of the manual effort for the production team. Ratec is continuously expanding its range of solutions and products in order to always have the right answer to future challenges.

Ratec presents itself at the Betontage Ulm from 20-22 June 2023 at booth no. 66.