New system for rapid waterproofing of concrete bridges

Meanwhile they have become the rule: headlines on bridges in Germany being ramshackle or even in danger of collapsing. The root causes for this situation are the corrosion of reinforcing steel in the concrete, the restricted load-bearing capacity and the lane grooves in the deck. Repair works or reconstructions are an inevitable consequence which, on the one hand, devour enormous amounts of money and, on the other hand, entail interminable blockings, detours and congestions.

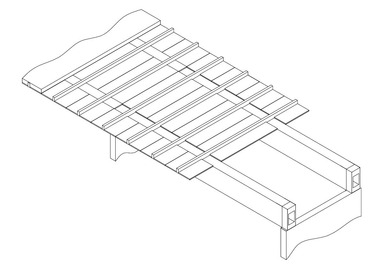

For one of these quite complex problems occurring when waterproofing concrete bridge decks underneath the asphalt surfacing, Sika Deutschland GmbH has developed two innovative systems: Sika HANV Rapid and Sika FLK Rapid help shorten the repair work drastically. The usually four to six weeks required for the repair work can be reduced to just one weekend – from removing the old deck surface, applying the waterproofing system to the installation of the new deck surface.

Resistant to deformation and immediately ready for traffic

The aim of these two systems is to avoid any cost-intensive delay in the repair works, thus further impact on the environment. Using the HANV method, a porous asphalt base course is directly applied to the concrete bridge deck in a layer thickness of 1.5 to 2 cm and subsequently filled with the two-component reaction resin Sika Ergodur-600. In this way, just one work step is needed to apply the shear resistant waterproofing system, realizing a surface that is resistant to deformation and immediately trafficable.

The modified polyethylene hot-meld adhesive Silkalastic-827 HT pellet, the second component of the HANV Rapid system, provides for an optimum bond of the waterproofing layer and the following rolled asphalt layer. This “hot to fresh” method realized by spreading additionally shortens the repair works. The protective layer, applied subsequently, consists of hot poured asphalt which melts the pellets, thus creating an excellent bond of the layers.

Liquid membrane as an alternative

The second Rapid waterproofing system of Sika also makes use of the holt-melt adhesive Sikalastic-827 HT pellets. But instead of flooding the asphalt base course with the epoxy reaction resin Sika Ergodur-600, a liquid membrane is used as a very quick deck waterproofing system. For this Sika FLK Rapid system, first the Sika Concrete Primer is applied, a solvent-free and rapid curing two-component primer based on polyurea for sealing cementitious substrates. It is directly followed by the waterproofing layer consisting of the liquid Sikalastic-841 ST membrane, which is manually spray applied with special two-part high-pressure hot spray equipment. The very fast curing and VOC-free pure polyurea creates an elastic, crack-bridging waterproofing layer with an excellent resistance to chemicals.

The independence form weather owing to just one work step, possible application underneath any asphalt surfacing, guarantee of an optimum bonding of all layers of the deck structure among each other and the reduction of traffic congestions, CO2 emission and the risk of accidents in the construction zone are further characteristics of both concrete bridge deck waterproofing systems.